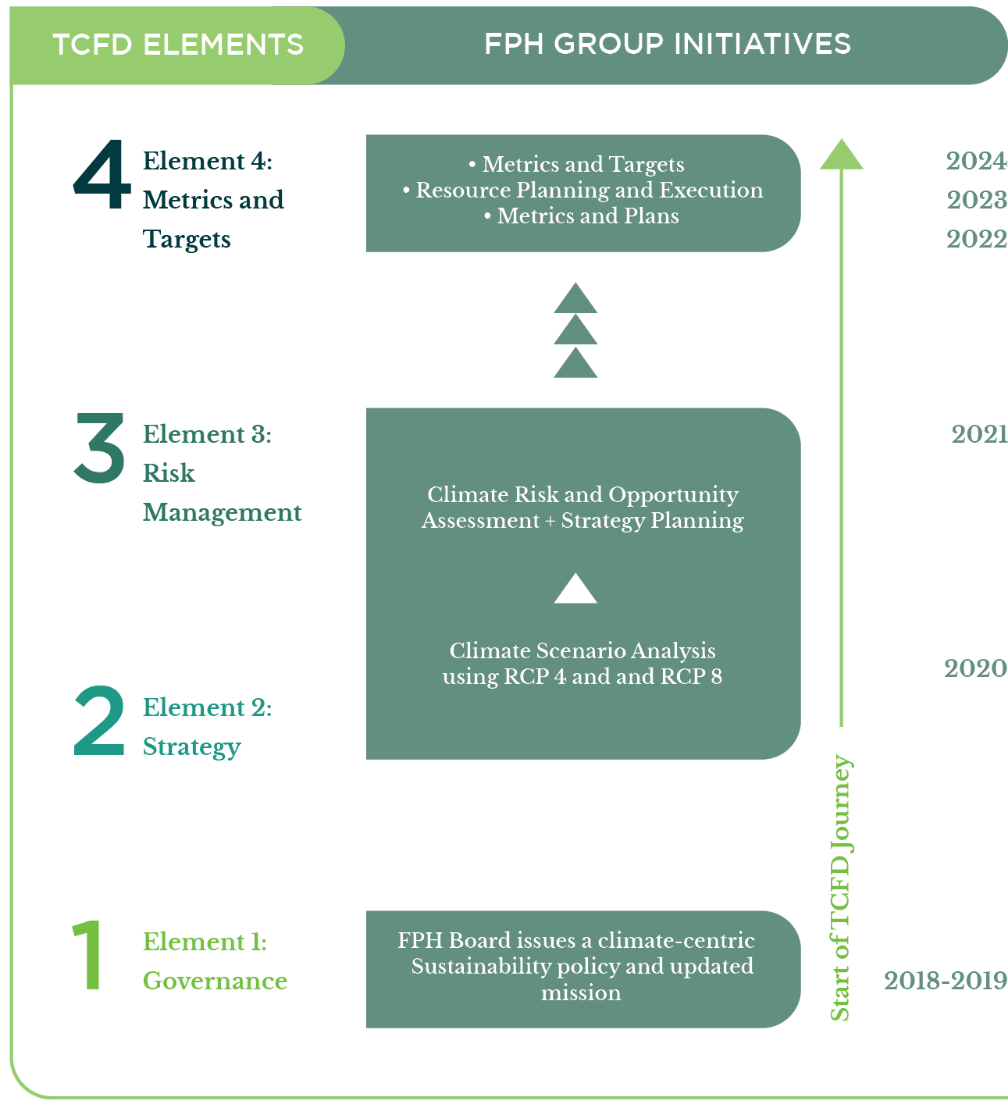

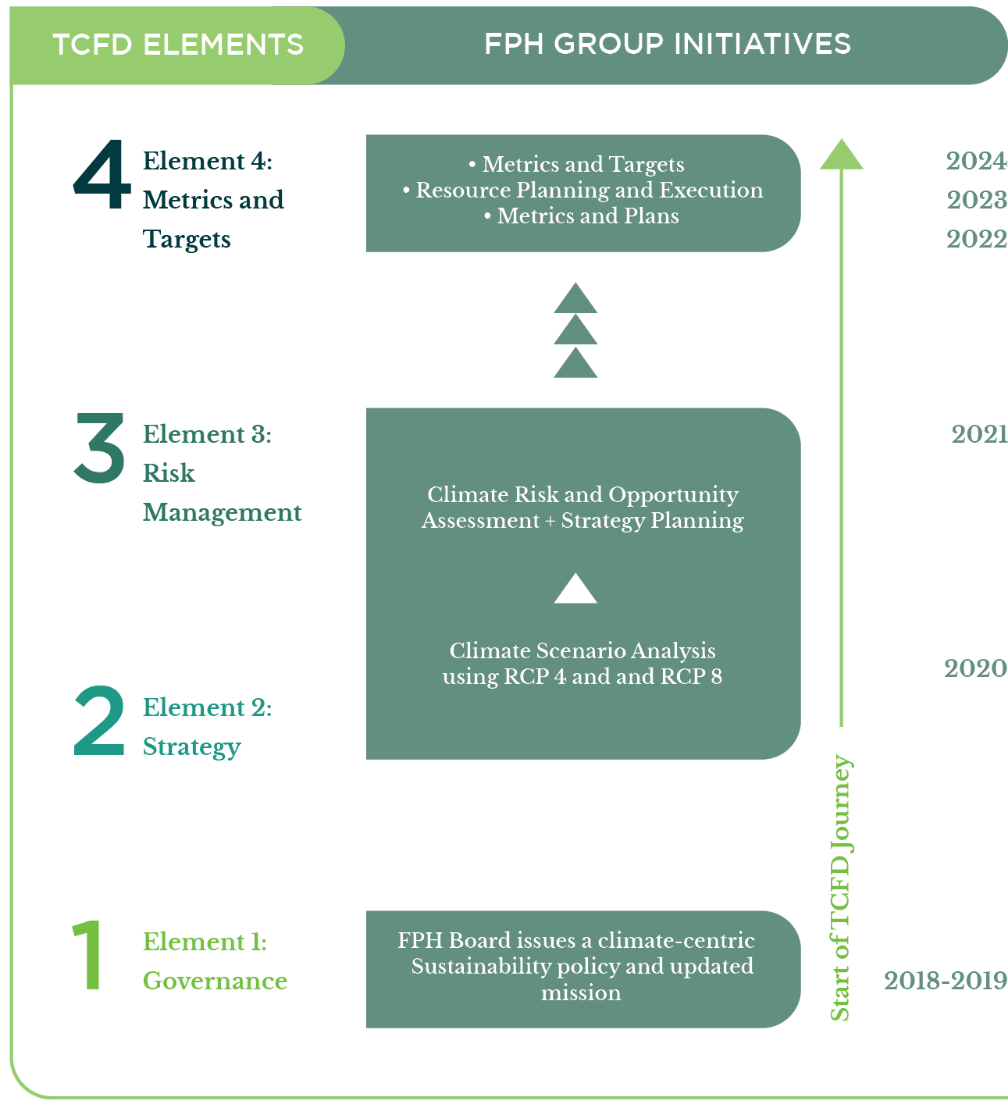

In 2018 to 2019, the FPH Sustainability Policy was formulated along with our updated mission of ‘To forge collaborative pathways towards a decarbonized and regenerative future’ to guide us in our TCFD journey.

Aside from our business risk assessments, First Gen—along with FPH and its other subsidiaries—also collaborated with the Oscar M. Lopez Center for Climate Change Adaptation and Disaster Risk Management Foundation, Inc. (OML Center) in 2020 and completed the scenario analysis for our various operating sites using the Representative Concentration Pathway (RCP 8.5 and RCP 4.5), or the projected cumulative concentration of GHG emissions that cause global warming. The assessment is decadal and there were minor changes in the projected climate risks except for a more heightened ambient temperature starting July 2023. That year stands as the highest in world records. Health measures for our workers have been updated but the rest of the measures are pursued and augmented.

These are the results of the OML Center’s assessment of First Gen’s physical risk scenarios analysis by 2050:

| PHYSICAL RISKS |

AFFECTED SITES | IMPACT TO THE BUSINESS |

|---|---|---|

| Increase in temperature |

Leyte, Bukidnon, North Cotabato, Ilocos Norte, Nueva Ecija, Batangas, Albay and Sorsogon, Negros Occidental |

High |

| Heavy rainfall | Metro Manila | Low |

| Sea level rise | Metro Manila, Nueva Ecija, Batangas | High |

| Tropical cyclones | Leyte, Bukidnon, North Cotabato, Ilocos Norte, Nueva Ecija, Batangas, Albay and Sorsogon, Negros Occidental | High |

This study, together with the super typhoons experienced by our operating assets a decade ago, made us more proactive about exploring and adopting several measures to address the climate-related risks we face. Some of these measures include the refurbishment and maintenance of our infrastructures, adopting the latest and appropriate technology to analyze physical hazards, and enhancing our administrative processes.

FIRST GEN’S OPERATIONAL RESILIENCY MEASURES

| INFRASTRUCTURE | CLIMATE-RELATED HAZARDS/RISKS ADDRESSED |

|---|---|

| Typhoon-proofing and reinforcement of power plant structures to withstand 300 kilometers per hour (kph) speed wind, as well as increased plant stability against earthquakes |

|

| Upgrading of cooling towers to Fiber Reinforced Plastic (FRP) |

|

| Flood control measures such as flood barriers, drainage declogging, and periodic inspections |

|

| Construction of shoreline erosion mitigation |

|

| Landslide mitigation measures |

|

| TECHNOLOGY | |

| Technology review for the structure’s wind defense mechanism, resulting in wind speed reduction of up to 66% before reaching the structure |

|

| Updating the Geohazard Map using the latest finer resolution Light Detection and Ranging (LiDAR) data to determine areas most susceptible to landslides |

|

| Water recycling technologies |

|

| ADMINISTRATIVE | |

| Strategic spares program for critical spares to ensure equipment damage is repaired and operations is restored/continued |

|

| Water assessment and management study |

|

| Regular inspection and maintenance of plant equipment and patrolling of areas to ensure readiness from climate hazards |

|

|

Exercise/drills following the established Emergency Response Plans Increasing forest fire lines to remove litter and other natural fuel |

|

We will carry on the utilization of our resources and execute the measures to mitigate the climate-related risks. We will also evaluate the effectiveness of these measures to further enhance the resilience of our assets and operations, thus fulfilling our obligations to deliver reliable, clean and renewable energy, and creating value to our stakeholders. For 2024, we aim to set appropriate targets from our previous data and metrics as baseline.

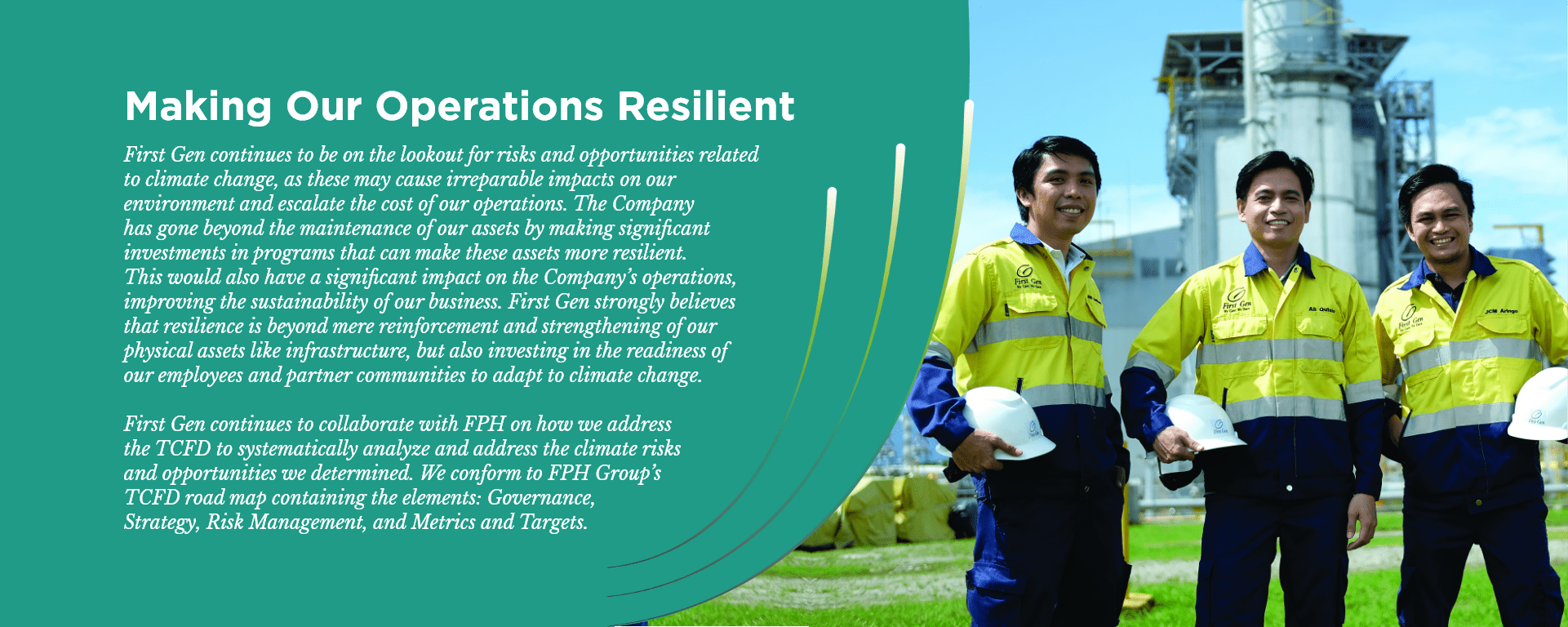

Impact on First Gen and our various stakeholders:

The resilient measures we employed enable us to withstand the various super typhoons experienced in our various operating sites, including super typhoon Yolanda in 2013. These efforts to make our operations stable provide power and uninterrupted service to our customers while ensuring the safety and security of our employees and the communities we live in.

Ensuring the Continuity of Our Business

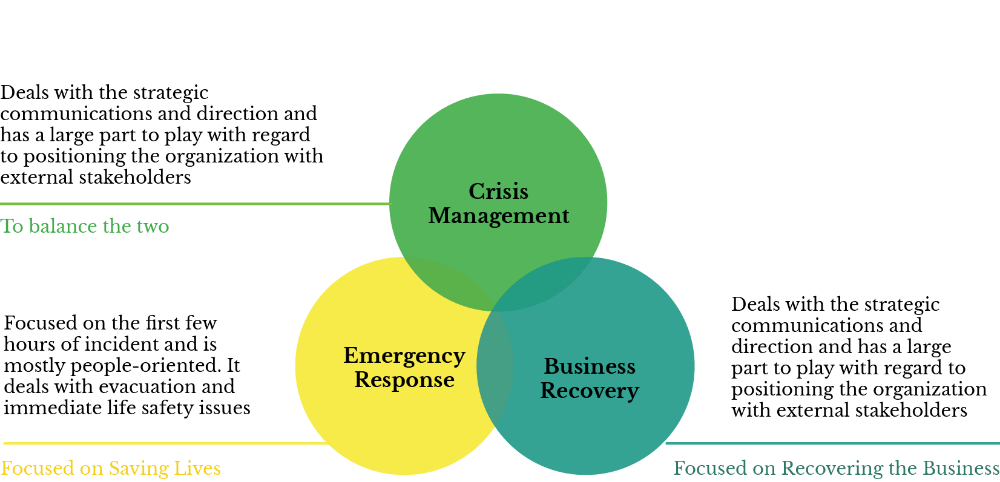

Aside from strengthening our structures, adopting new technologies, and employing administrative measures to withstand climate-related risks, we also ensure that the business continues to operate amid crisis and emergency situations through our Business Continuity Management System (BCMS).

First Gen’s BCMS sets a strategic and operational framework to increase corporate resilience during emergencies. BCMS aims to: a) protect lives by empowering the workforce with the skills and knowledge on disaster preparedness in order to recover and make their families resilient during any disaster; and b) protect the business by setting in place a Business Continuity Management Plan to provide structure to manage any crisis and sustain mission critical activities during any disaster. Our BCMS covers the management of personnel, infrastructure, cybersecurity, business, communications, and operations to ensure readiness in times of emergencies. Emergency scenario assessments and business impact analysis also cover potential site-specific scenarios resulting from climate-related catastrophic events.

THE BCM FRAMEWORK

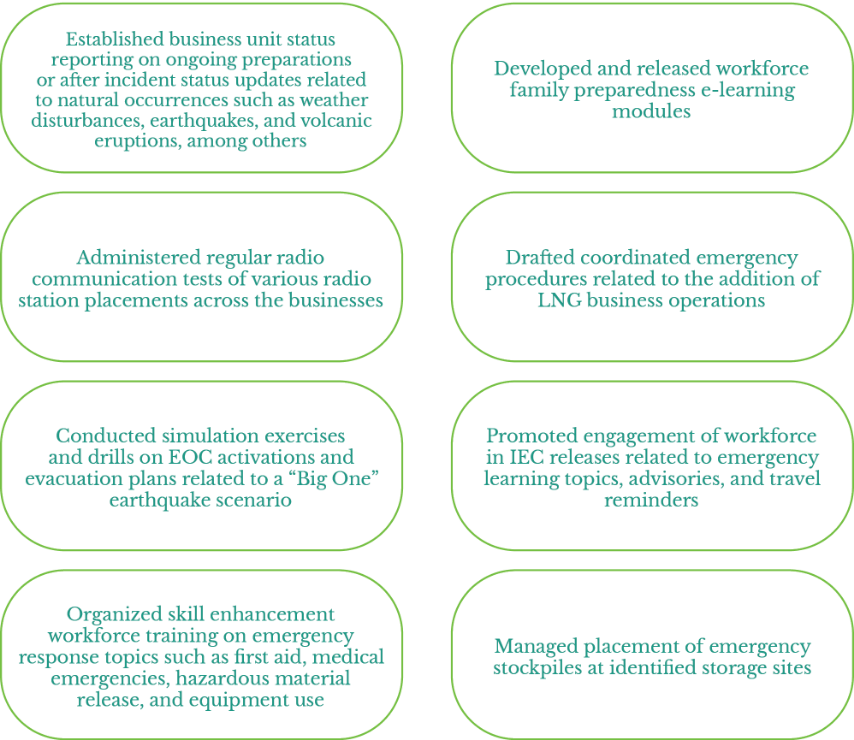

First Gen’s BCMS Strategy aligns with the core elements and the continual improvement of plans to prepare and respond at the onset of disaster scenarios. The plans cover items such as priority actions taken, organizational roles and responsibilities, communications and direction, infrastructure, equipment, training, and mission-critical activities, among others.

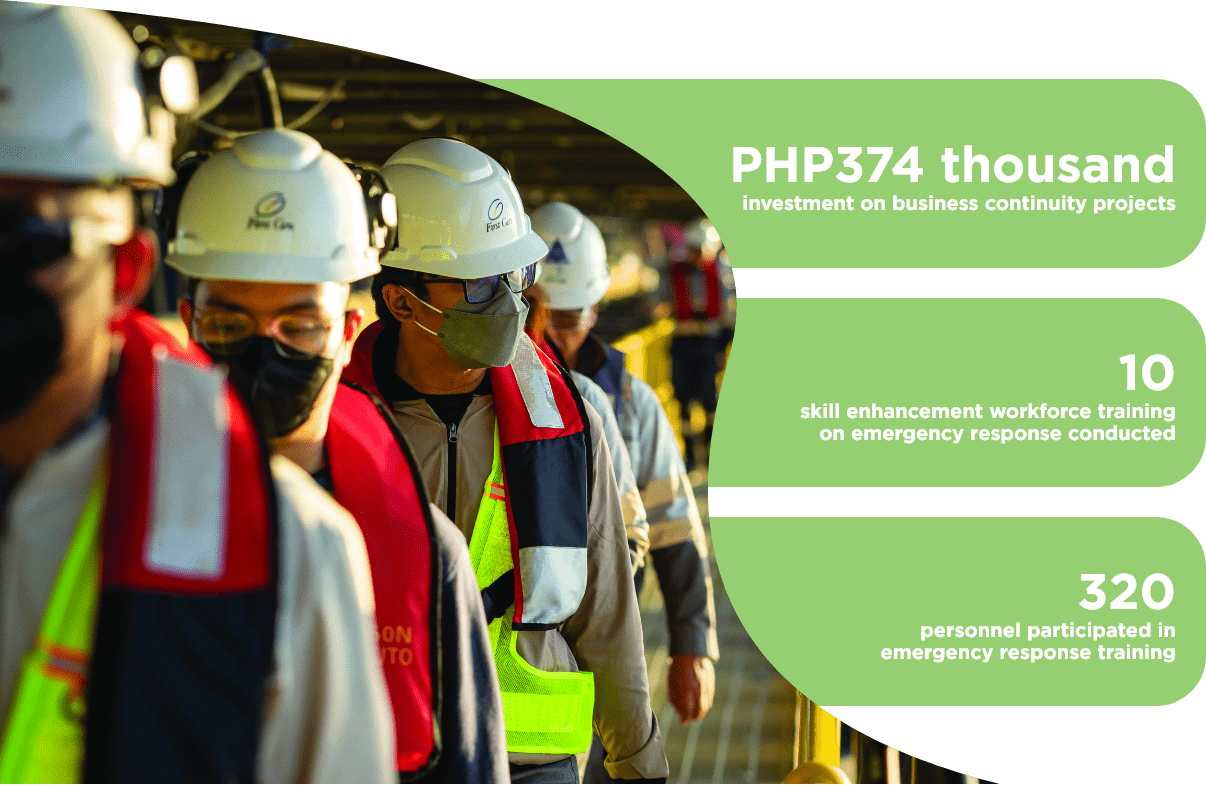

First Gen has invested PHP374 thousand on business continuity projects to set-up our Emergency Operations Center (EOC) and to develop, prepare, and utilize First Gen and FPH’s various enterprise business resources for emergency response. The EOC enables collaboration among First Gen and FPH businesses in the areas of disaster response communication, information, planning, personnel, and response activities.

KEY DEVELOPMENTS INVOLVING BCM IN 2023:

First Gen will continue to partner with FPH in building the capability of the Company and the whole FPH Group to support the BCM framework. Our efforts to make our business and operations resilient and ready for catastrophes manifest our commitment to our customers to produce and serve reliable power. They also instill confidence in our employees and communities that we operate in a safe manner.