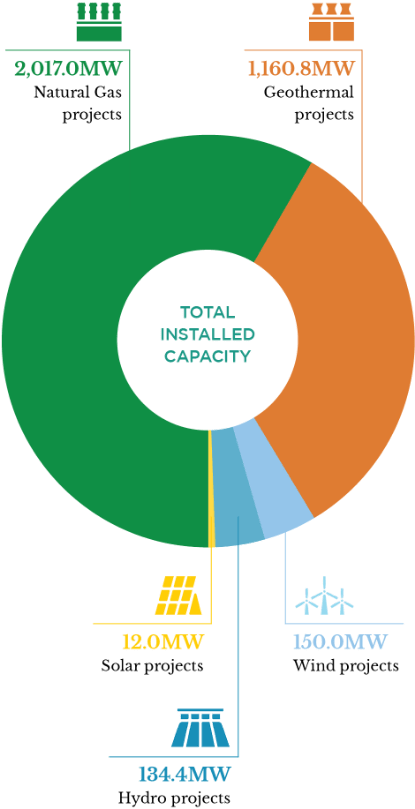

Using a combination of clean and low-carbon sources, First Gen delivers reliable power to our customers while minimizing the negative impact on the surrounding communities and environment. The Company’s manufactured capital comprises 31 power projects all over the Philippines that have a combined installed capacity of 3,474.2MW. In 2023, they generated a total of 21,604.5GWh and powered 19.3% of the Philippines.

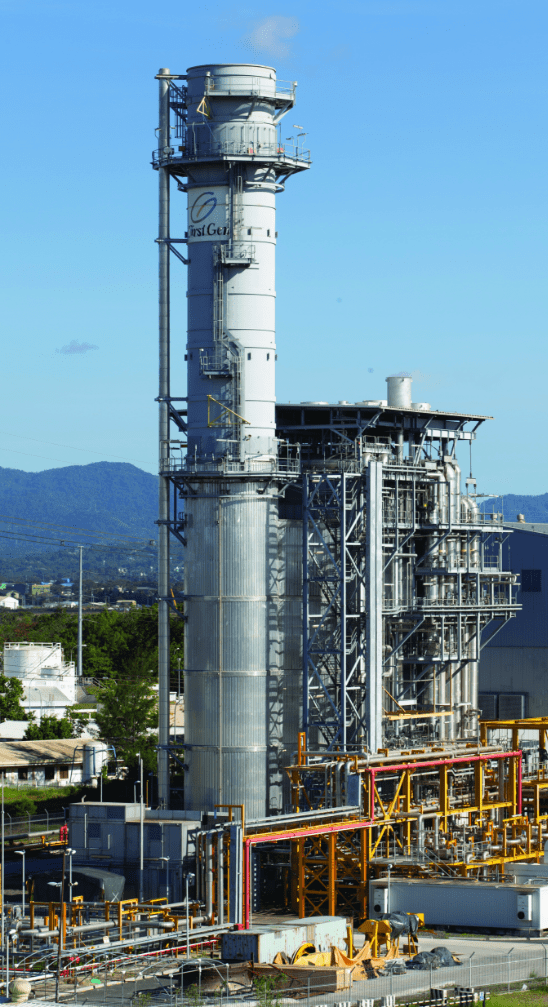

Natural Gas

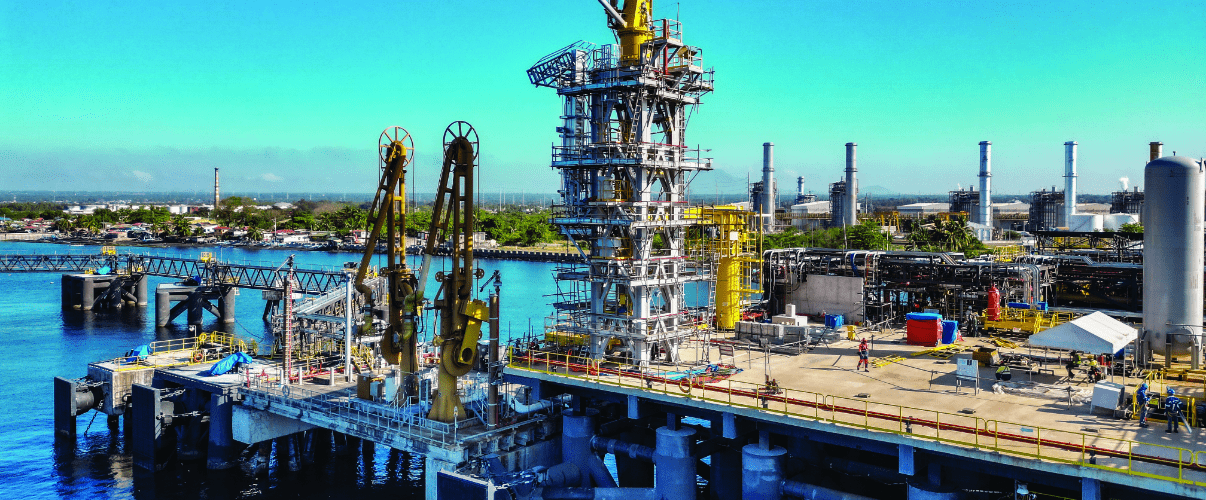

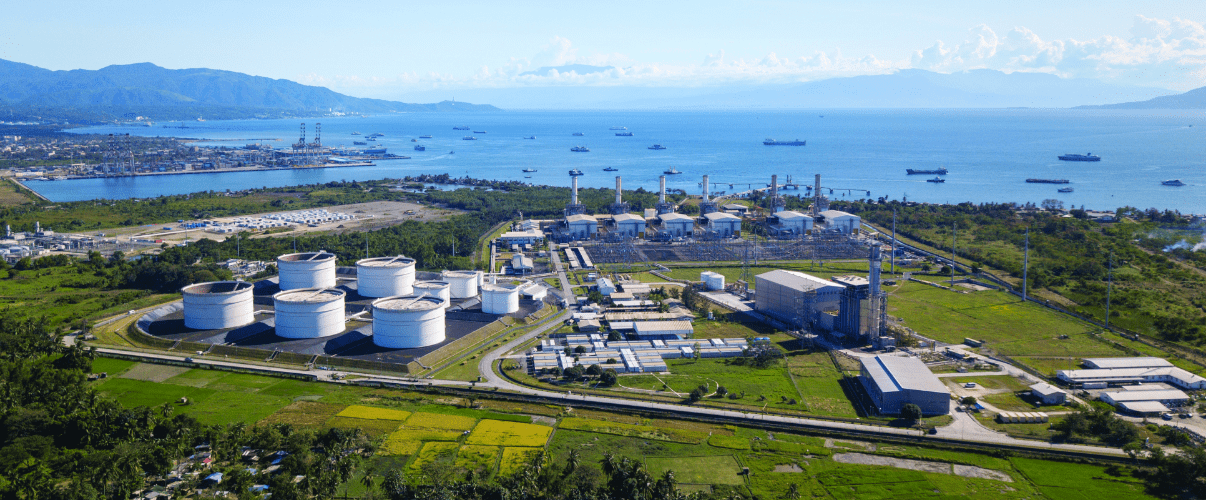

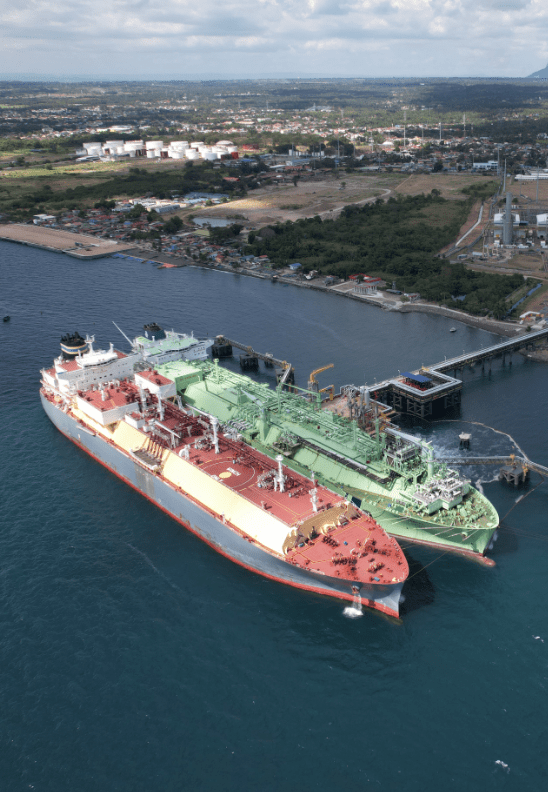

The natural gas supply from Malampaya for 2023 was below the requirements of the First Gen Clean Energy Complex (FGCEC) plants due to the continuing depletion of the gas field. As a result, there were instances when the Santa Rita and San Lorenzo power plants operated on condensate fuel in place of natural gas.

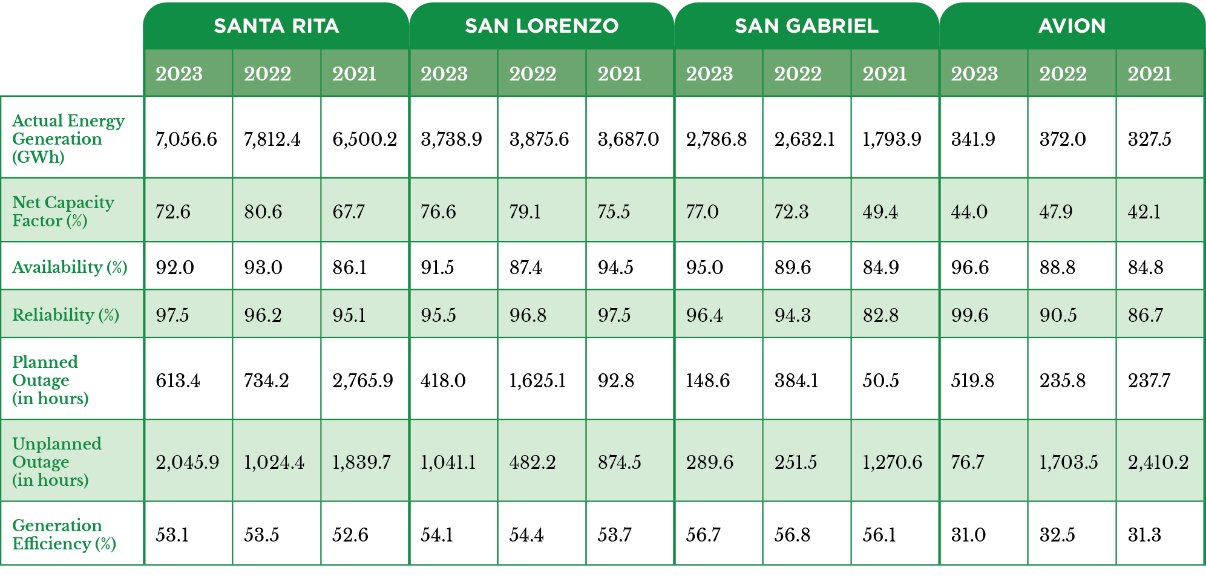

The natural gas power plants overall produced less power in 2023 than 2022. This was due to unplanned outages from Santa Rita and San Lorenzo, wherein certain units or systems needed rectification; and where Avion’s output decreased despite its high availability and reliability mainly due to a shift from the energy market to ancillary services and partly because of lesser opportunities at the WESM as a result of high power reserves of the grid. In contrast, the output of San Gabriel increased compared to the previous year with less planned outages and high dispatch rates.

With the continuing depletion of gas supply from the Malampaya Gas Field, the available supply of natural gas was not enough to sustain First Gen’s gas plants. There had been instances in 2023 where the Santa Rita and San Lorenzo plants operated on liquid fuel in its place. Despite this, the power plants managed to maintain its operations based on dispatch. In response to the ongoing decline of Malampaya gas supply, First Gen’s gas plants commenced with being commissioned to run on LNG on Q4 2023. Two LNG deliveries were received within the year for their commissioning to use regasified LNG.

Several 2021 and 2022 figures have been adjusted. Please refer to the Restatements section for the summary of changes.

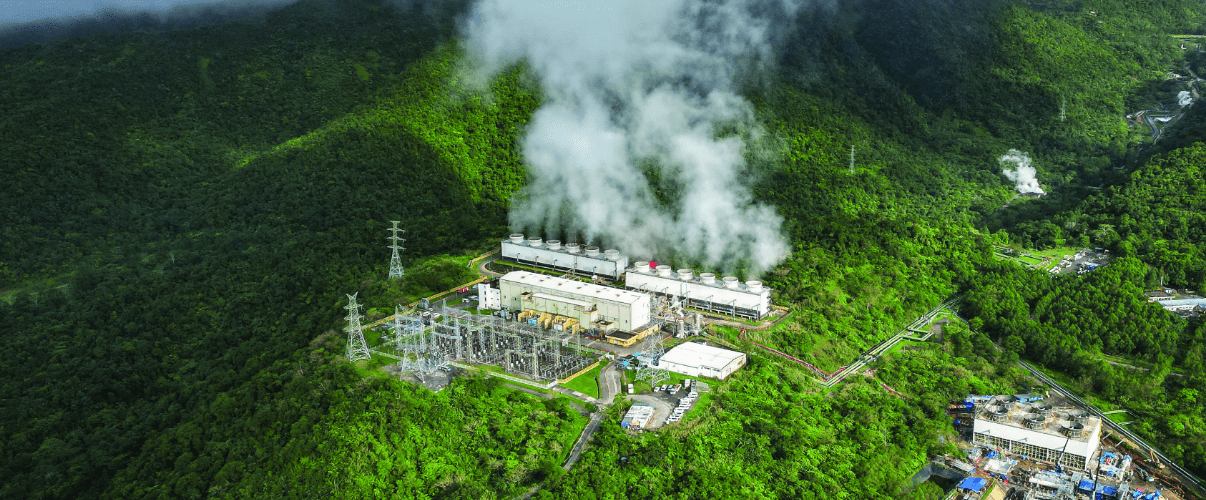

Geothermal

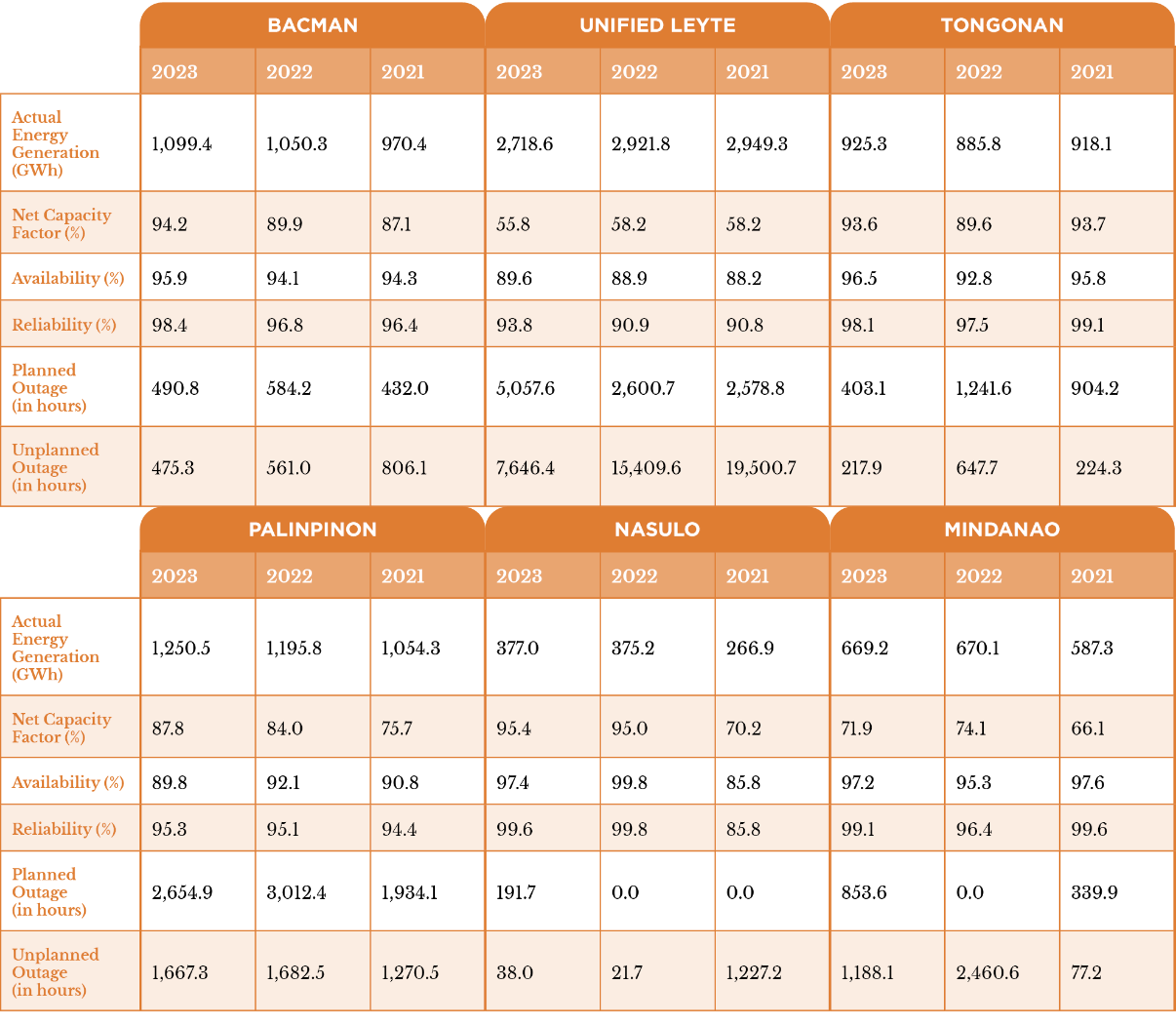

First Gen’s Leyte and Mt. Apo plants saw an increase in generation versus the targets for 2023, primarily through technological advancements and improvements in operational efficiency. Meanwhile, the Negros and Bacman sites had lower generation than the target due to technical problems detected in the facilities, particularly with a generator rotor in the Negros site and the initial turbine rolling in Bacman. These issues have been detected and addressed in a timely manner, with both sites resolving them by the first half of 2024.

Work continues for the Palayan Binary Project, the Tanawon Geothermal Power Plant, the Mahanagdong Geothermal Brine Optimization Plant, and the Battery Energy Storage Systems (BESS) projects in Tongonan, Southern Negros, and Bacman. First Gen ensures that these projects continue to comply with all local and national regulations during their construction and prioritizes safe man hours and HSE-compliant working conditions.

First Gen, through EDC, was able to fulfill obligations to our contracts in 2021 to 2023 through generation from our plants. During outages, the maintenance allowances on these contracts were invoked. For maintenance allowances that are fully utilized, or for contracts with no maintenance allowance, EDC purchases from the WESM to fulfill said contracts.

Several 2022 figures have been adjusted. Please refer to the Restatements section for the summary of changes.

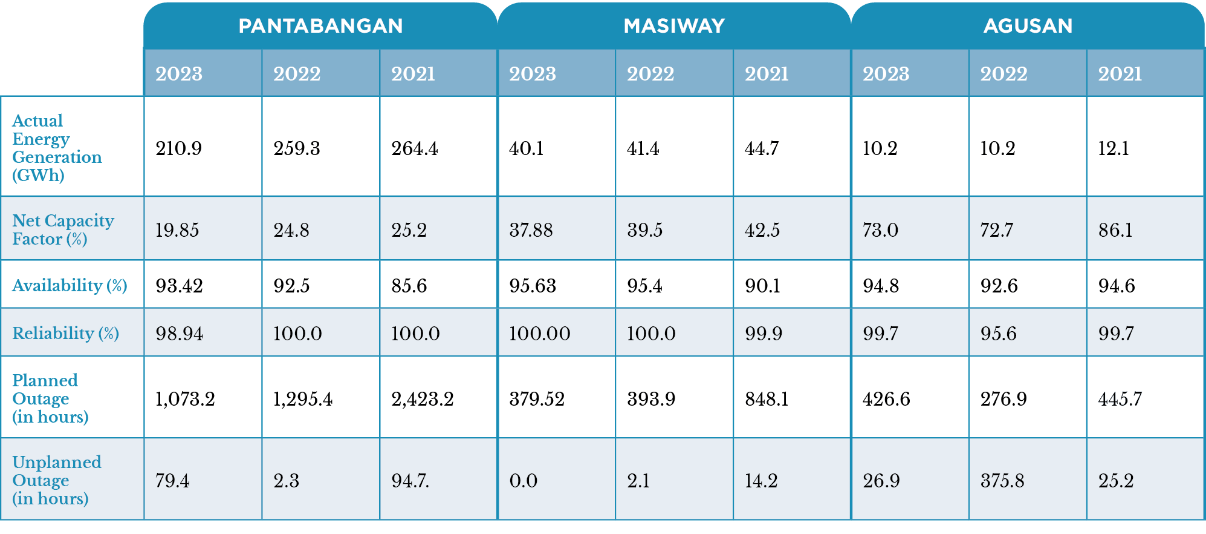

Hydroelectric

FIRST GEN HYDRO POWER CORPORATION (FGHPC)

December’s Year-To-Date (YTD) gross generation declined by 19.70 percent from 303.10gWhs in 2022 to 249.86gWhs in 2023 due to the comparatively lower Pantabangan reservoir water elevation for the first half and last quarter of 2023 compared to 2022. This greatly affected the dependable capacity or capability of the Pantabangan hydroelectric plant (HEP) to generate electricity.

The Ancillary Services sales for 2023 also significantly declined compared to 2022 due to the expiration of FGHPC’s ASPA contract with NGCP effective March 2023. Renewal of ASPA is through Competitive Selection Process (CSP) as required by the DOE and ERC. However, the Company did not apply for ASPA for Regulating, Contingency and Dispatchable Reserve services as the requirement is for generators offer to be “FIRM”, or continual offer throughout the contract period, of which the plant cannot provide, having a cyclical or seasonal generation only. First Gen is looking at offering A/S again when the Reserve Market commences commercial operation in the first quarter of 2024.

Overall, FGHPC was able to fulfill our contracted PSAs as well as our energy offers to the IEMOP for 2023. As of December 25, 2023, our contracted capacity is at 41.77MWs. However, due to the challenges mentioned on the Pantabangan water level at the reservoir and in anticipation of the onset of El Niño, we are looking at further reducing our contracted capacity to around 28MWs or lower for 2024. This can be done by transferring some of our PSAs to EDC and/or non-renewal of our expiring short-term PSAs, particularly for contestable customers engaged by our RES.

FG BUKIDNON POWER CORPORATION (FGBPC)

FGBPC obtained approval from the IEMOP as WESM Direct Member and Trading Participant (Generation Company Category). The WESM membership is effective January 12, 2023. During the process, FGBPC coordinated with the system operator (NGCP) for the plant to fit with the technical requirement considering that the plant systems are manually operated.

Just like in prior years, the PSA between FGBPC and CEPALCO also reached full compliance. Minor comments/ feedback on communications which affect the hourly/ data reporting of plant data have also been addressed.

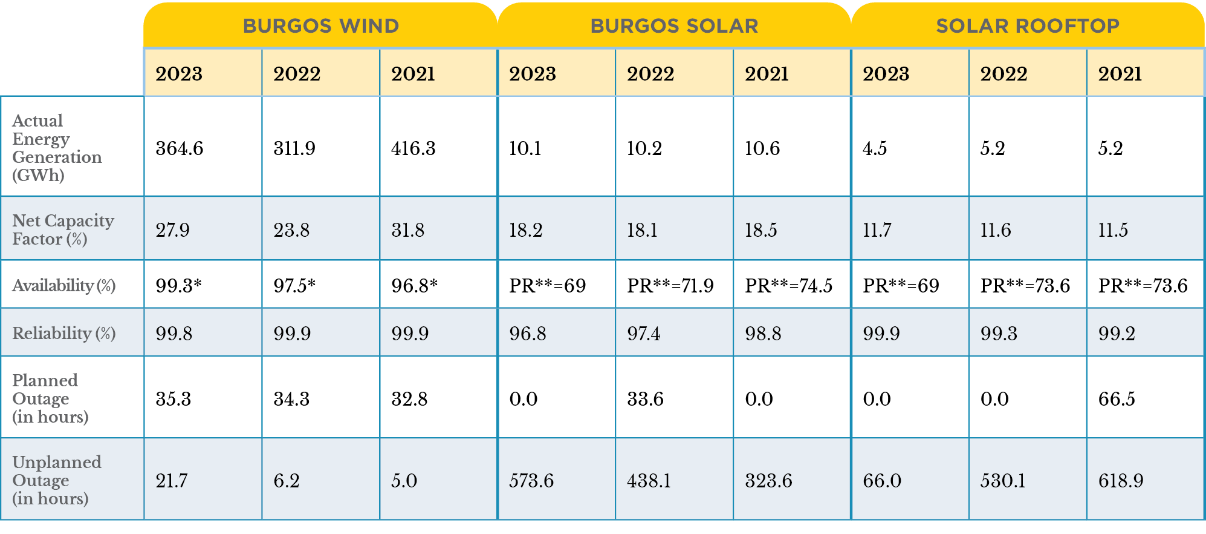

Wind and Solar

In 2023, the Burgos site was affected by stronger winds from Low Pressure Areas (LPA) in January and November and Typhoons Mawar (Betty) in May and Egay (Doksuri) in July.

Typhoon Egay brought about strong winds that caused the outage of five Wind Turbine Generators (WTG). Our typhoon inspections discovered that the units suffered Arc Flash Damage. With only one spare transformer, the Company had to source replacement transformers from Denmark and the USA. The outage has an estimated loss of 12.56GWh. With careful planning, the spare parts were delivered before the year ended, and the Wind Turbines were restored to full operation by the second week of November. Damaged WTGs were restored between August 28 to November 13, 2023.

The FiT rate for wind (applicable for the years 2016-2020) underwent escalation as per the Energy Regulatory Commission (ERC) Resolution No. 6, Series of 2020, titled “A Resolution Approving the Adjustment to the Feed-In Tariff (FiT),” which was officially published on November 17, 2020 and took effect on December 2, 2020. The resolution stipulates a five-year duration for the actual recovery of arrears.

Accordingly, entities with the January 2016 generation period were invoiced in December 2020 and received payment in January 2021. This payment cycle has continued in subsequent months, adhering to the five-year recovery period outlined in the resolution. We have diligently collected these arrears on a monthly basis since the commencement of this process.

On February 19, 2021, the ERC issued a letter to Transco, indicating that, until the approval of the 2021 FiT-All rate and the adjustment of FiT rates, the initially approved FiT rates should be applied for the billing related to the 2021 generation. As of now, no approval has been granted for the FiT rates for the years 2021, 2022, and 2023.

As of the end of September 2023, the EDC Burgos Wind Power Corporation’s (EBWPC) receivables from Transco amounted to approximately PHP2.4 billion.

* Energy-based availability * Performance ratio (PR). Ratio of measured output to expected output for a given period and based on the system name-plate rating.

Due to the proactive nature of our COVID-19 management since the onset of the pandemic in 2020, the operation and production of First Gen’s plants have continued or not been impeded. Many adjustments and efforts were made on the ground to protect the workers, including sheltering in place in 2020 and vaccination of more than 90% of employees and contractors, which led to uninterrupted service by the Company to our customers and communities.

As such, the only significant change to plant complex generation is the ability to remotely operate plants in a designated area outside of the control rooms to ensure continual plant operation, even when plant operators are not physically present at the plant.

Plants, including support personnel, have successfully transitioned to 100 percent face-to-face operations and have effectively adapted to the new normal. COVID-like symptoms in employees, if any, are managed with the use of basic personal protective equipment (PPE) and house isolation for a short duration of time, if necessary. Part of the new normal is also the availability of work-from-home arrangements, which are allowed on a case to case basis.

Enforcing minimum public health standards like masking, physical distancing, and hand hygiene is now ingrained as routine practice. Robust campaigns for COVID vaccination as well as other respiratory conditions such as flu and pneumonia were also conducted to reduce the incidence of disease. In addition, improvements to ventilation through Carbon Dioxide Level Assessment were conducted at work sites.

Moving forward, the Company will emphasize vaccination, ventilation, and minimum public health standards. The focus is to make the company “pandemic-proof” through the enhancement of existing protocols and guidelines, applying the learnings from COVID-19. First Gen will continue to support a hybrid work setup for our operations, allowing our employees the greatest degree of flexibility to fulfill their roles while also ensuring the continual smooth operation of our facilities.

The upgrade of FGHPC’s Computerized Maintenance Management System (CMMS) was also approved in late 2023. This initiative aims to implement a more reliable and permanent enterprise asset management (EAM) solution that will address plant operation requirements and the performance management of our physical assets. Further, this shall prevent the loss of maintenance history/records, as the CMMS so ware (Infor EAM Version 10.1) and its operating system (Windows Server 2008) are already obsolete. FGHPC also initiated the upgrading project of our control system for Public Health Emergency Preparedness (PHEP) in late 2023. This is a three-year project, culminating in 2025.

For office environments, carbon dioxide sensors were purchased to assess the ventilation in all meeting rooms. Carbon dioxide can be used as an indicator of adequate air exchange in a workspace. This initiative is in accordance with DOLE 224-21 entitled “Guidelines on Ventilation for the Workplaces and Public Transport to Prevent and Control the Spread of COVID-19”, which states that “...a level of 1,000 parts per million (ppm) of carbon dioxide, as detected by carbon dioxide sensors has been established as the maximum threshold for which a room can be considered safe, and well ventilated.” This initiative has enabled the Company to safely implement curated face-to-face work opportunities in our hybrid setup while exercising optimal infection prevention control.

Kandao video conferencing equipment has also been made available. Employees can request the use of Kandao equipment in our meeting rooms to improve virtual interactions

Lastly, the Company has also purchased an additional Dongfeng Rich 6 EV to complement our Nissan LEAF EV used by site employees in FGCEC for official business trips. Using the EVs reduces our carbon emissions by approximately two tons per year, compared to using vehicles powered by diesel or gasoline.

The Resiliency Compliance Plans for FGPC, FGP, FNPC, PMPC were submitted to the DOE in 2018. The plans included emergency response measures under the categories of system, stockpiling, response and recovery, and strengthening infrastructure. The documents also discussed the establishment of an Emergency Response Team, Emergency Response Plan, Emergency Drills, and Maintenance of Fire and Protection Systems and Firefighting equipment. Programs on the monitoring of emergency supplies inventory, and spares and consumables inventory on a periodic and regular basis were also tackled.

An updated Resiliency Compliance Plan was submitted to the DOE in May 2023. The plan includes emergency response measures completed from 2018 to 2023. This includes the completion of Flood Tsunami Protection in 2021 (Storm Surge Protection) and the Shoreline Erosion Mitigation Project in 2023, among others, and helps to mitigate flooding in the complex during typhoons and heavy rains. All other reported projects and programs are still being implemented at the power plants. The Department of Energy raised no concerns regarding the submitted plans.

The Company has also continued the engineering controls, such as the Cooling Tower Replacements in Leyte and the Building Retrofitting Projects. As a result, First Gen does not have Landslide Mitigation (LMM) projects at our geothermal sites for the first time. Because of the continuous proactive mitigation we have done in the previous year, we have maintained the landslide risk level across sites at low to medium. In 2023, we completed another two cooling tower replacements in Leyte, completing the upgrade of all nine cooling towers in Leyte. First Gen also completed three building retrofitting projects in Leyte, Negros, and BacMan, with completed 12 LMMs in Leyte and Negros. EDC has reduced natural catastrophe (Nat Cat) risks to a medium level, and we will continue our risk mitigation effort to maintain the current risk level.

First Gen has also invested in studies that will help us refine our risk assessments and identify necessary risk reduction measures, such as the Building Integrity Assessments of other old power plant buildings. The first batch of buildings under the current retrofitting program were constructed in the 1980s and designed based on the old building code of 1976. We now want to look at the actual conditions of buildings built in the 1990s and designed based on the old building code of 1992. In 2023, we conducted another batch of Building Integrity Assessments to check the actual conditions of buildings built in the 1990s.

The Company has also drafted the EDC’s Head Office Business Continuity Management Plan (HO BCM Plan) to cover “The Big One” Scenario. This is aligned with the Department of Energy’s National Energy Contingency Plan (NECP) for “The Big One.” In 2023, we established the high level strategy for EDC Head Office’s BCM Plan for“The Big One”, which is aligned with the Parent Company’s strategy. All corresponding initiatives to ensure that we have a working BCM plan will be continued in 2024.

First Gen has also implemented various emergency response management activities in our Burgos plants, our geothermal facilities, and our corporate head office. These include the conduct of relevant emergency response training, drills, stockpiling of emergency supplies, and updating of relevant emergency response guidelines.

The highlights of FGHPC’s Resiliency Plan for 2023 are the Refurbishment of Housing Compound Suppression System (amounting to PHP11.3 million) and the Gas Suppression System for the Pantabangan and Masiway HEP Control Rooms, including the the Fire Suppression System for Electrical Cabinets (amounting to PHP12.0 million).

For FGBPC, the plant’s Resiliency Plan in 2023 includes strengthening infrastructure activities/projects. These include, among others, the Riverbank Restoration project and the Main Diversion Weir Toe Repair and Improvement.

First Gen remains committed to our Net-Zero goals. Our plants and facilities push initiatives related to the development of low-carbon energy solutions and contribute to our targets on the share of low-carbon sources in total power generation or capacity.

FGPC, FGP, FNPC, and PMPC have adopted the plantations in the Pantabangan-Carranglan Watershed Forest Reserve (PCWFR) for the establishment, maintenance, replanting, and enhancement planting activities in the 1,209-hectare plantation as a potential carbon offsetting option, which has an average carbon sequestration potential of 22,900 tons per year. We also continually monitor updates on emerging technologies that can decarbonize our gas plants, such as carbon capture technology and using alternative fuels such as hydrogen.

In December 2023, solar panels were installed on the rooftop of the Avion site’s car park, comprising a total of 80 solar PV modules with a total actual power generating capacity of 44kW. Energy produced by the Avion Solar PV Panels is used to supply power consumption within the Avion Power Plant compound and other equipment.

FGHPC successfully conducted our Level 1 Energy Audit as required by the DOE for PHEP, being a type 1 Designated Establishment (DE). Although MHEP is classified as “other” DE, we conducted an internal energy audit as well to determine compliance with the requirements of RA 11285 and its Implementing Rules and Regulations (IRR). For our compliance, two FGHPC employees underwent rigorous training and accreditation processes to become DOE- accredited energy auditors. As clarified by DOE, however, an independent investigation should be conducted. As such, we engaged a third party provider, WESTCO Electrical & Equipment Corp., that reviewed and certified the energy audit report of our energy auditors.

As a certified ISO 14001 company, FGHPC had environmental targets for 2023, one of which was the reduction of our residual waste by five percent. This translates to a target reduction of our residual waste disposed at the municipal waste facility from 75.50 tons to 67.95 tons or by 7.55 tons. However, our actual reduction rate was 11.26 percent as we were able to reduce our residual waste to 8.5 tons.

FGBPC continued the implementation of its Water Consumption Management, which is set to be improved in 2024 (repiping of water systems and installation of additional monitoring meters), and the energy conservation program, including the gradual replacement of its lighting system with LED lighting fixtures. With the Enercon program in place, FGBPC was able to control and reduce its energy consumption by around 16MWh in 2023—150.69MWh compared with 166.67MWh in 2022.

Other First Gen decarbonization efforts are pursued together with EDC, such as the completion of our Greenhouse Gas Accounting Pre-Assurance. This project was completed in 2023 in order to identify improvement opportunities in the GHG emissions accounting and reporting processes of First Gen and EDC, in order to prepare the organization for an external limited assurance in the next few years.

The Company has also partnered with EDC to roll out the Zero Carbon Gateway online platform to our Net Zero Carbon Alliance (NZCA) partners, as a way for them to track their net zero journey based on the NZCA framework. NZCA closed 2023 with a total of 21 partners (from 12 in 2022) coming from various Philippine industry sectors.

Alongside EDC BINHI, First Gen continuously upholds its commitment to protecting the natural flora and fauna of the Philippines, as well as supporting the communities that function as their natural caretakers and safeguards. Alongside our commitment to net-zero operations and our continual development of low-carbon solutions, the Company hopes to keep our operations in line with our Mission, Purpose, and Chosen Path.