First Gen, as an energy company, is committed to the preservation and regeneration of our natural resources. As we continue our journey in the implementation of our Mission “to forge collaborative pathways for a decarbonized and regenerative future,” we take the lead in transitioning to a decarbonized energy system and continuous integration of regeneration strategies in the conduct of our business operations to ensure the protection, preservation, and improvement of the environmental conditions in the areas and communities that we operate.

We are highly dependent on harnessing our planet’s natural resources to produce clean, renewable, and affordable electricity for the Filipino people and we are committed to its environmental stewardship and protection in order to contribute to the regeneration of our ailing planet. We firmly believe that to heal our Earth, First Gen will need to take firm action in addressing the challenges of climate change through a multi-year strategic plan to reduce our carbon footprint in alignment with the Philippine government’s energy transition plan and ambition to significantly increase renewable energy, natural gas capacities and decrease our dependence on coal. The government program aims to increase the share of renewable energy to 35 percent by 2030 and 50 percent by 2040.

As we continue to develop, grow, and build on our platform of renewable and low-carbon energy assets, with the target of achieving an additional 13GW of clean energy by 2030 for a greener Philippine electric gid, our business strategy will continuously involve the responsible utilization and preservation of our natural resources for the welfare of our current and future generations. Our mission, our business strategy and our Environment, Safety and Health (ESH) Policy are the guiding directions as we continue to create value in our energy portfolio for both our manufactured and natural capital.

As stated in our ESH Policy, First Gen commits to the preservation and enhancement of the environment. We maintain an Environmental Management System (EMS), covering our business development, project monitoring, and asset management activities to reduce environmental emissions, effluents, wastes and promote the efficient use of energy, water, and other resources. The EMS of our subsidiaries: FGPC, FGP, FNPC, PMPC, FGHPC, FGBPC and EDC likewise maintain individual certifications to the ISO 14001:2015. We annually review our environmental risks to ensure the effectiveness of our mitigation strategies for environmental protection and preservation. Consistent with the EMS protocols, all our subsidiaries undergo the annual audits conducted by the Corporate Quality, Environment, Safety and Health (QESH) team and their respective certifying body. The ESH Policy is posted on the Company’s website and can be accessed through this link.

With the environmental programs in place, First Gen has no incidents of non-compliance with environmental standards and regulatory requirements of the country.

The Greenhouse Gas (GHG) emissions of First Gen were generated from using natural gas as the primary fuel for First Gen’s combined-cycle gas turbine (CCGT) power plants and other renewable energy technologies, such as hydropower, geothermal, solar, and wind. These emissions affect various sectors of the economy and energy supply security.

Context of GHG Emissions Inventory and Reporting Boundaries

| ORGANIZATIONAL BOUNDARIES |

OPERATIONAL BOUNDARIES |

| In accounting for our GHG emissions, First Gen adapted the operational control approach in establishing our organizational boundaries with the power plants included in our diverse portfolio of natural gas and renewable energy. |

- Scope 1: Direct emissions from power generation operations

- Scope 2: Indirect emissions from purchased electricity.

- Scope 3: Indirect emissions from supply chain

- 2021-2022 – coverage is only for Category 7: Employee Commuting

- 2023: coverage includes:

- Category 3: Fuel and Energy Related Activities

- Category 5: Wastes Generated in Operations

- Category 7: Employee Commuting

|

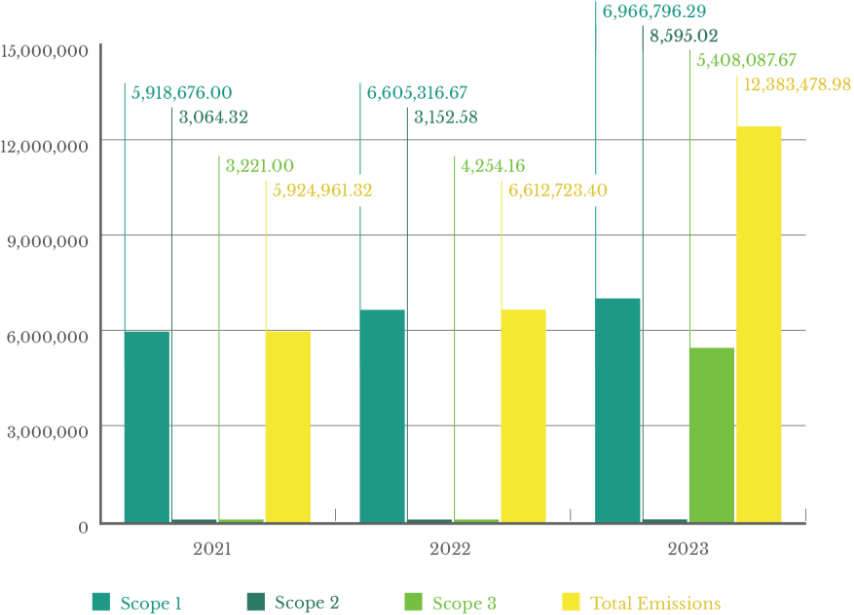

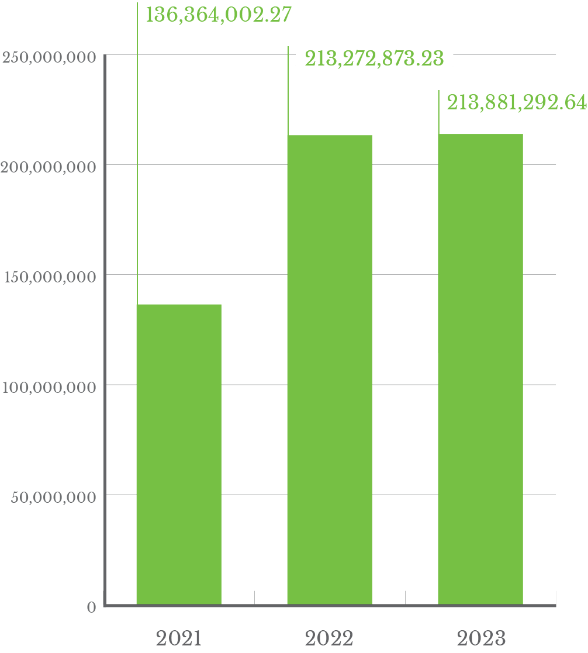

FIGURE 1: TOTAL CARBON EMISSIONS (IN TONNES CO2e)

*The 2021 and 2022 figures have been adjusted. Please refer to the Restatements section for the summary of changes

The observed increase in total emissions from 2022 to 2023 in Figure 1 is due to the increase in our Scope 1, 2, and 3 emissions. The majority of the increase in our total emissions is due to the inclusion of Scope 3 indirect emissions accounting for fuel and energy related activities and wastes generated in our operations. This is the result of the 2023 capacity building sessions on Scope 3 accounting that was implemented by the Corporate Sustainability Group (CSG) of our parent company FPH.

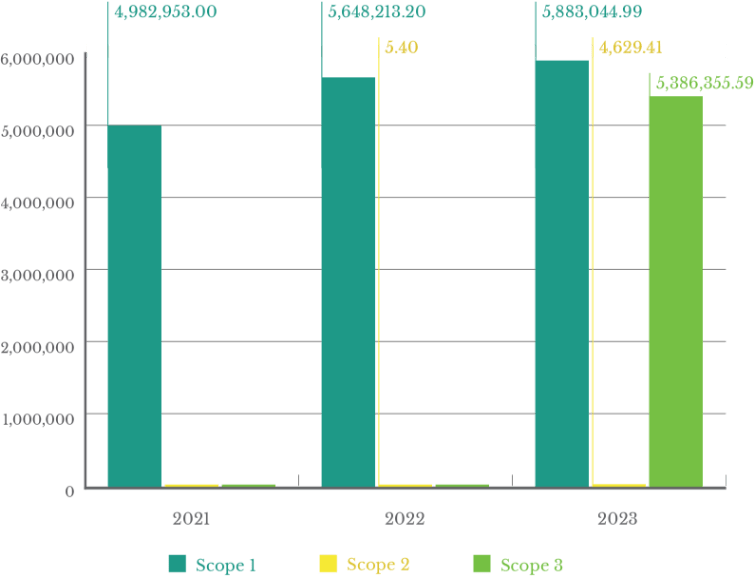

FIGURE 2: NATURAL GAS CARBON EMISSIONS (IN TONNES CO2e)

The natural gas platform in FGCEC makes up 84 percent of First Gen’s Scope 1 emissions. In 2023, the natural gas supply from Malampaya Gas Field was below the requirement of the FGCEC Plants due to the continuing depletion of the gas field resource. As a result, our Scope 1 emissions for our natural gas plants increased due to the use of liquid fuel as an alternative fuel for our Santa Rita and San Lorenzo power plants in lieu of natural gas in order to continue its power generation activities. Condensate fuel and diesel were utilized during periods of low natural gas supply to ensure the uninterrupted operations of the Santa Rita, San Lorenzo, and Avion power plants. Furthermore, our Scope 2 emissions also increased as a result of purchased electricity from the grid to support the power requirements of our power generating facilities.

With the completion of the FGEN LNG Interim Offshore Terminal (IOT) in 2023, its commissioning and commercial operations shall mitigate these emissions by ensuring a constant supply of natural gas thereby significantly decreasing the use of liquid fuel. The business and operational objectives of the IOT were realized during the commissioning of the power plants on liquified natural gas (LNG) in the fourth quarter of 2023 in response to the ongoing decline of gas supply from Malampaya. Two LNG deliveries were received by the IOT in 2023 for the commissioning of the power plants using regasified LNG.

The IOT also has the potential of enabling other natural gas industries in boosting our national transition to decarbonization, as we are committed in our strategy in the development of our natural gas business as a necessary step in our journey towards decarbonization and regeneration, with natural gas as the transition fuel to continue supporting the DOE’s Philippine Energy Plan (PEP 2040).

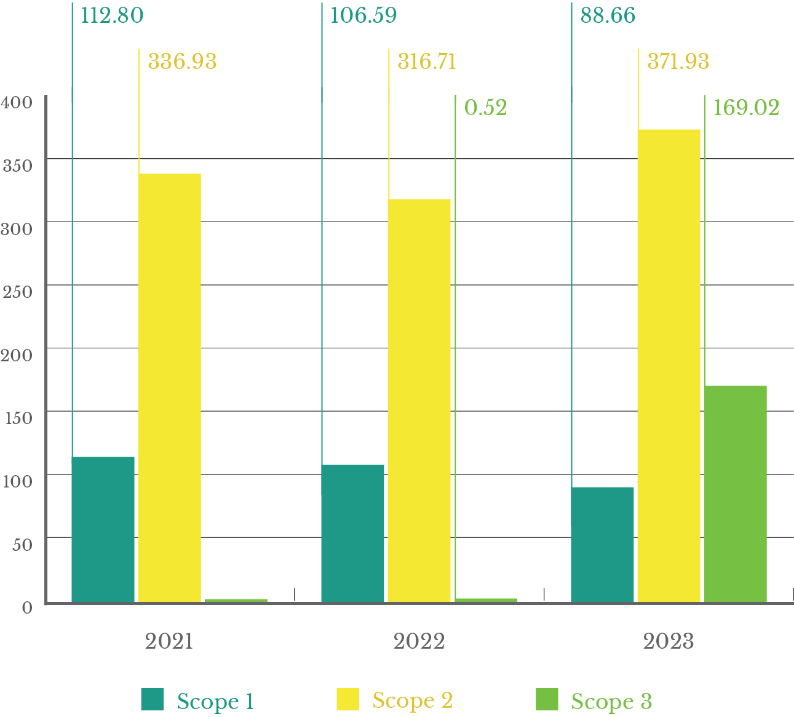

FIGURE 3: HYDRO ELECTRIC CARBON EMISSIONS (IN TONNES CO2e)

For our hydroelectric power plant operations, our Scope 2 emissions increased because of the increased consumption of purchased electricity from the grid to support the power generation activities.

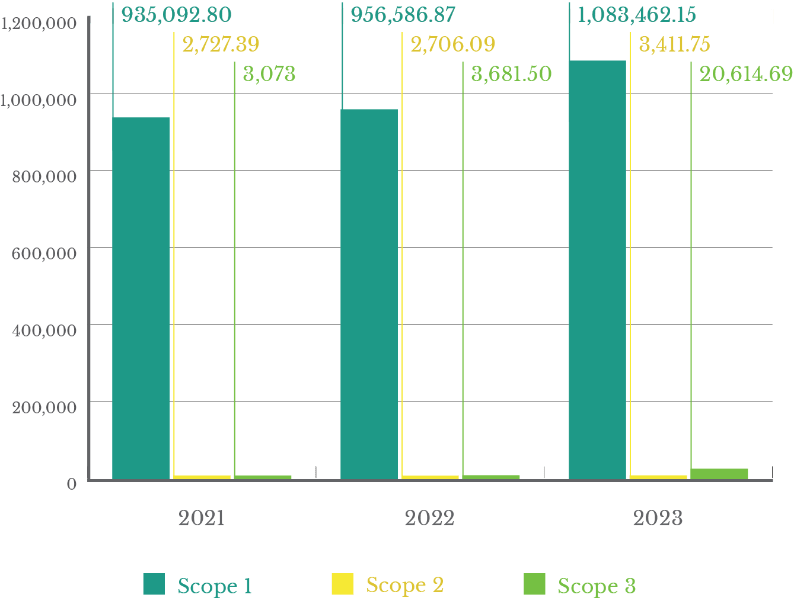

FIGURE 4: GEOTHERMAL/SOLAR/WIND CARBON EMISSIONS (IN TONNES CO2e)

*The 2021 and 2022 figures have been adjusted. Please refer to the Restatements section for the summary of changes

The Scope 1 emissions of EDC, our renewable energy subsidiary for geothermal, solar and wind power generation is 16 percent of the overall total of First Gen emissions. The increase in EDC’s 2023 Scope 1 emissions was mainly due to the increase in steam consumption resulting in higher power generation.

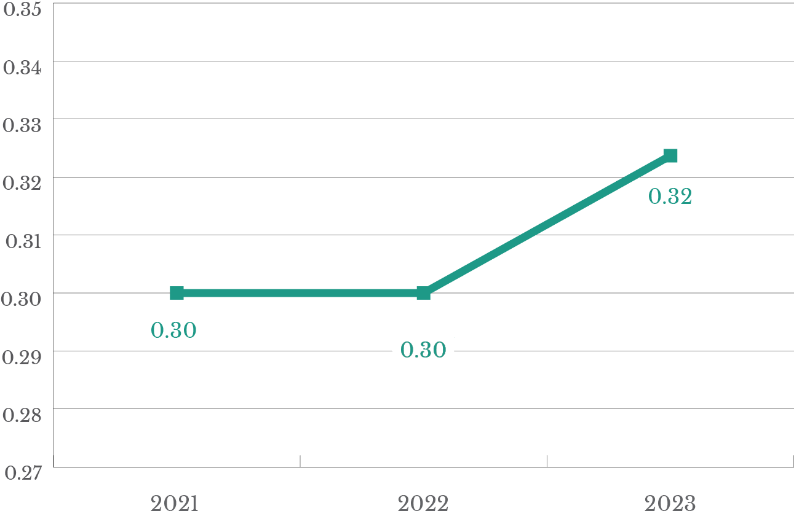

FIGURE 5: FIRST GEN OVERALL EMISSION INTENSITY

*The 2021 emission intensity has been adjusted. Please refer to the Restatements section for the summary of changes

First Gen’s emission intensity in 2023 was 0.32 compared to the 2022 emission intensity of 0.30 as shown in Figure 5. This change was attributed to the increase in the GHG emission intensity of FGCEC in 2023 compared to 2022, primarily due to the increase in liquid fuel consumption. The increase in the steam consumption of EDC also contributed to the increase in Scope 1 emissions. For our 2023 natural capital performance, the amount of carbon emissions generated from producing the same amount of energy of 21,604.5GWh is 61 percent lower than a coal-fired power plant. Moreover, producing power using our clean and renewable energy, prevented the release of 10,740,303.6 tonnes of greenhouse gas emissions (tCO2e), equivalent to the removal of approximately 2,556,212 gasoline-powered passenger vehicles in one year.

We are constantly monitoring updates on emerging technologies that can further decarbonize our gas plants, such as carbon capture technology and using alternative fuels such as hydrogen, batteries, and other clean energy options.

Other Emissions Affecting Air Quality

Aside from GHG, we consistently monitor our other emissions to comply with regulatory standards. The measured concentrations of these pollutants were significantly lower than the emission limit values set under RA 8749 (Philippine Clean Air Act) due to the dry-low NOx technology, embedded in the plants’ combustion systems. The total emissions and the emission intensity are shown in the table below.

TABLE 1: OTHER SIGNIFICANT AIR EMISSIONS

| EMISSION |

WEIGHT IN TONNES |

EMISSION INTENSITY IN TONNES CO2e

PER GIGAWATT HOUR (TONNES/GWh) |

| 2023 |

2022 |

2021 |

2023 |

2022 |

2021 |

| Carbon Monoxide (CO) |

684.82 |

615.8 |

849.1 |

0.05 |

0.04 |

0.07 |

| Nitrogen Oxides (NOx) |

3,476.49 |

3642.3 |

2945.3 |

0.25 |

0.25 |

0.24 |

| Sulfur Oxides (SOx) |

237.40 |

355.3 |

623.0 |

0.02 |

0.02 |

0.05 |

| Particulate Matter (PM) |

204.04 |

147.1 |

341.7 |

0.01 |

0.01 |

0.03 |

Decarbonization Initiatives Implemented

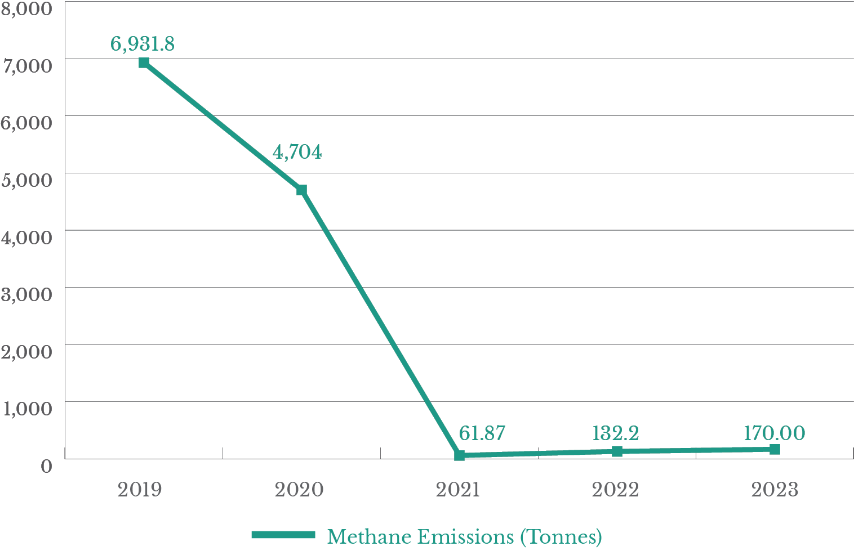

Methane Fugitive Emission Management Program

FGCEC continues to implement the Methane Fugitive Emission Management Program which started in July 2020. The program aims for the early detection of fugitive emissions using an optical gas imaging camera, resulting in the rectification of gas leaks and reduction of fugitive methane gas emissions from gas leakage. FGCEC’s total fugitive methane emission in 2023 was equivalent to 170 tonnes of CO2e which was 97.58 percent lower than the 2019 baseline. FGCEC conducts these natural gas leak surveys twice a year, which contributes to the periodic identification of leak sources and the performance of immediate corrective maintenance activities to address them. In 2023, there were no leaks detected from the two completed surveys.

FIGURE 6: FGCEC METHANE FUGITIVE EMISSIONS REDUCTION PERFORMANCE

*The 2019 value indicated in Figure 6 is the average of estimated fugitive methane emission from 2015-2019

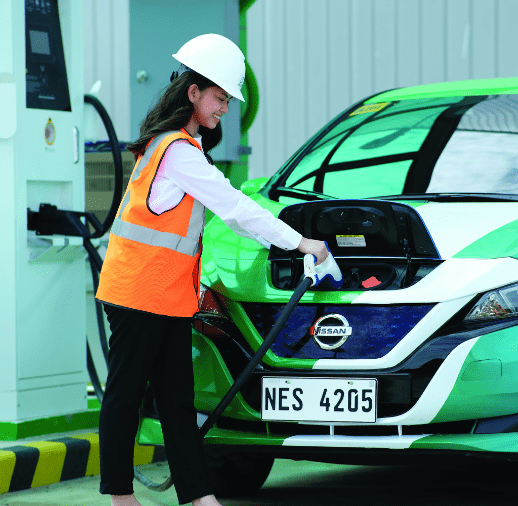

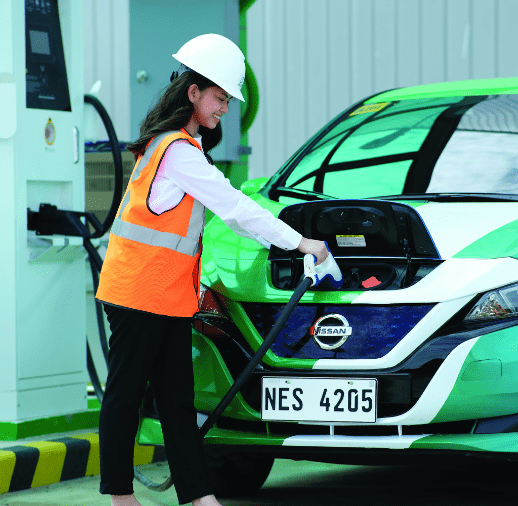

FGCEC Electric Vehicle (EV) Initiative

In 2023, FGCEC purchased another electric vehicle (Dongfeng Rich 6 EV pick up vehicle) for the transportation needs of the employees in the complex. This complements the Nissan LEAF EV that was purchased in 2022 which is used by the employees in our site for official business trips. By using the EVs, we were able to avoid approximately 2 tonnes of carbon emissions per year compared to using vehicles powered by diesel or gasoline.

GHG Assurance Project - Readiness Assessment for External Limited Assurance of GHG data

As part of its decarbonization strategy, First Gen has identified that the accurate measurement and reporting of its emissions profile is essential to further enhance the organization’s capability in ensuring that the GHG monitoring and reporting systems in place are in accordance with global industry standards. This is in order for our organization to be assured of having an accurate and reliable GHG data reporting system that is being used in the different disclosures of the company to various external stakeholders and investors.

In 2023, First Gen engaged the services of ERM Certification and Verification Services (CVS) to conduct an assurance readiness review of the 2022 Scope 1 and 2 emissions profile of our FGCEC natural gas plants and EDC geothermal plants in the Philippines as the sample data for the simulated assurance exercise which was undertaken in accordance with ISO 14063:3 for the GHG verification of greenhouse gases. As a result of the assurance readiness review, First Gen will be working on the development of the recommended improvements to prepare the organization for the external limited assurance of its Scope 1 and 2 Emissions.

Scope 3 Capacity Building Project

In the last quarter of 2023, the CSG engaged the services of Engie Impact Pte. Ltd. (Engie Impact) to facilitate virtual and onsite capacity building sessions related to the concept of Scope 3 GHG emissions inventory and accounting. During the 13 weeks of project implementation, Engie Impact conducted four capacity building workshops for FPH subsidiaries and provided assistance in the development of Scope 3 footprints at entity-level and group-level. For each entity in project scope, the deliverables include value chain mapping and materiality assessment, detailed insights on data quality and calculation, and Scope 3 footprint with hotspot analysis. Using the available data for 2022 as the subject of the exercise, the total computed 2022 Scope 3 values for First Gen was 1,085,813 tCO2e where 94 percent of the values were primarily contributed by Scope 3 Category 3 – Fuel and Energy related activities.

2022 SCOPE 3 FIRST GEN

EMISSIONS CALCULATED

BY ENGIE IMPACT |

TOTAL

EMISSIONS

(tCO2e) |

% PER

CATEGORY

VS TOTAL |

Category 1

Purchased Goods & Services |

57,188 |

5.27% |

Category 2

Capital Goods |

8,605 |

0.79% |

Category 3

Fuel & Energy Related |

1,015,470 |

93.52% |

Category 4

Upstream Transportation &

Distribution |

3,127 |

0.29% |

Category 5

Wastes Generated in Operations |

333 |

0.03% |

Category 6

Business Travel |

858 |

0.08% |

Category 7

Employee Commuting |

232 |

0.02% |

|

1,085,813 |

100.00% |

Furthermore, as a result of the Scope 3 Capacity Building Project, First Gen was able to identify the current gaps and improvement opportunities in its existing procurement and accounting processes. Addressing these gaps will enable a practical, sustainable and accurate Scope 3 data collection and processing as part of First Gen’s continual improvement for GHG emissions accounting and reporting requirements. Based on the assessment and recommendations of Engie Impact, First Gen will be working on addressing these gaps starting in 2024 to improve our Scope 3 emissions inventory and accounting for material categories.

Clean Energy Advocacy

The Net Zero Carbon Alliance (NZCA) is an initiative of First Gen-owned EDC, the country’s pioneer and largest pure renewable energy company. Established in September 2021, NZCA is EDC’s response to its mission “to forge collaborative pathways for a decarbonized and regenerative future.”

As the country’s first initiative spearheaded by the private sector to achieve net-zero carbon emissions among businesses, NZCA seeks to inspire and assist Philippine businesses in taking immediate steps to achieve carbon neutrality by 2050 and contribute to the country’s efforts to address its climate crisis.

NZCA provides its partners with a framework to achieve its goal by sharing best practices, scaling up carbon emission reduction and tracking, and providing better access to green financing, among many other capacity- building tools.

In 2023 EDC rolled out the Zero Carbon Gateway online platform to its NZCA partners to track their net zero journey based on the NZCA framework. NZCA closed 2023 with a total of 21 partners (from 12 in 2022) coming from various Philippine industries.

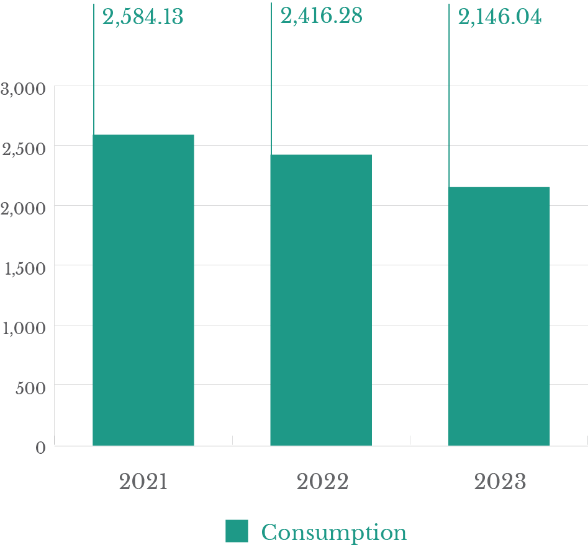

First Gen’s energy consumption for power generation originates from raw sources and electricity purchased from the grid. As shown in Figure 7 below, the increase in energy consumption for 2023 is attributed to the increase of utilization of non-renewable energy sources compared to the previous year.

FIGURE 1: TOTAL CARBON EMISSIONS (IN TONNES CO2e)

FGCEC Solar Panel Installation

FGCEC installed solar photovoltaic (PV) panels on its properties to significantly reduce the GHG emissions caused by house load power demand. The solar PV panels fall under the category of “change in fuel or power technology.” In addition to the solar PV panels installed at the FGCEC administration building and San Gabriel warehouse, the installation of solar panels at the Avion parking lot were completed in 2023.

In 2023, the solar PV panels at the administration building generated 47,848.58kWh. Meanwhile, the solar PV panels in the San Gabriel Warehouse generated 289,560kWh. The solar lamp posts in Avion which were also installed in 2022 have an estimated 87,066kWh or 313.44GJ of energy reduction in 2023.

The solar panel PV panels that were installed in the Avion parking lot back in December 2023 have a total actual power generating capacity of 44.0kW. The energy that will be produced by the Avion solar PV panels will be used to supply the power consumption within the Avion power plant compound and other equipment.

Energy Audits

In 2023, our other First Gen subsidiaries, EDC and FGHPC completed their respective energy audits. EDC engaged the services of Pi Energy Inc. as an accredited DOE Energy Service Company (ESCO) to perform the baseline energy audit across EDC subsidiaries. This ensures our compliance with DOE’s Department Circular 2019-11-0014 (the Implementing Rules and Regulations of RA 11285 Energy Efficiency and Conservation Act), as well as giving us a better understanding of our energy performance and usage.

FGHPC successfully conducted its Level 1 energy audit as required by the DOE for Pantabangan Hydroelectric Plant (PHEP), being a type 1 Designated Establishment (DE). While on the other hand, we also conducted an energy audit for our Masiway Hydroelectric Plant (MHEP) and First Gen Hydropower Plant Housing Compound even though it is not required by DOE since it is classified as other DE, to determine compliance to the requirements of RA 11285 and its IRR. The energy audit reports for PHEP and MHEP were certified by WestCo which is also a DOE accredited ESCO.

Other Energy Efficiency Initiatives Implemented

FG Bukidnon’s decarbonization strategy includes the energy conservation program which covers the gradual replacement of its lighting system with LED lighting fixture. Through the implementation of energy conservation program, FG Bukidnon was able to control and reduce its energy consumption by around 16MWh in 2023 compared with that of 2022.

Water Use

Water is a vital resource for First Gen since its serves as a primary source of power generation in its hydroelectric plants, with secondary operational use as a coolant for our natural gas and geothermal plants. It also provides the domestic water needs for all our assets. All First Gen power plants regularly monitor water withdrawal to ensure compliance with the extraction rate limits set by the National Water Resources Board (NWRB) for groundwater and seawater.

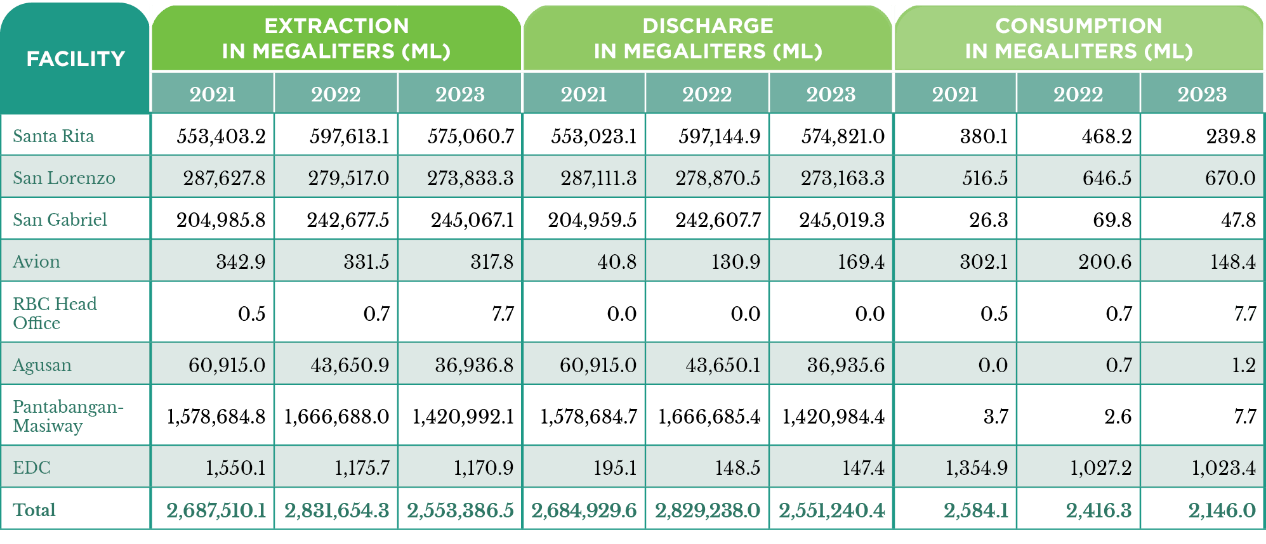

TABLE 2: VOLUME OF WATER EXTRACTION, DISCHARGE AND CONSUMPTION PER FIRST GEN FACILITY

*The 2022 and 2021 water figures were adjusted. Please refer to the Restatements section for the summary of changes

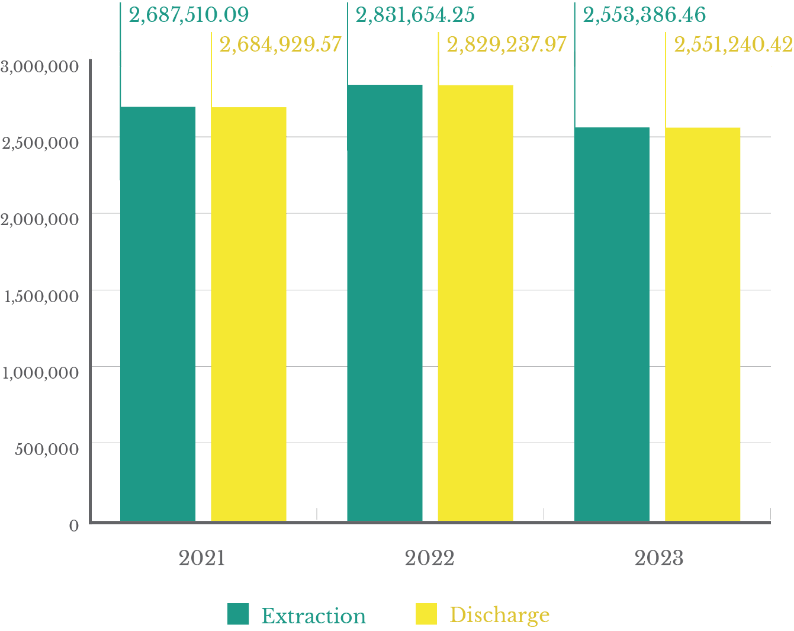

FIGURE 8: FIRST GEN OVERALL WATER EXTRACTION & DISCHARGE (IN MEGALITERS)

*The 2022 and 2021 water figures were adjusted. Please refer to the Restatements section for the summary of changes

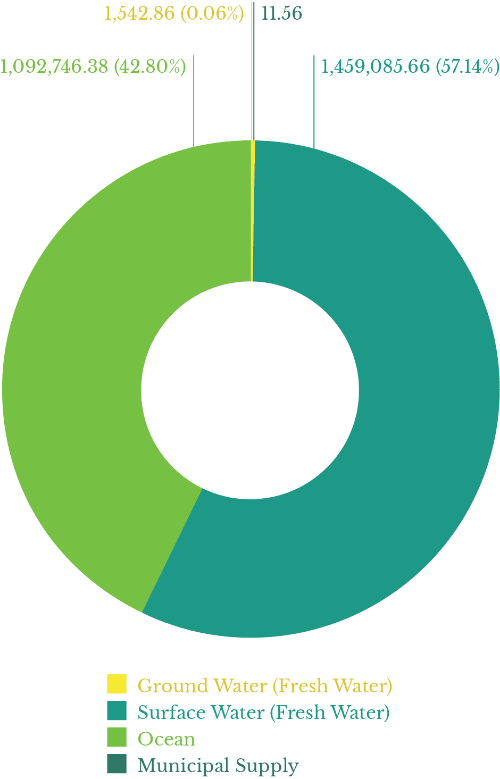

FIGURE 9: FIRST GEN SOURCES OF WATER (IN MEGALITERS)

FIGURE 10: FIRST GEN OVERALL WATER CONSUMPTION (IN MEGALITERS)

*The 2022 and 2021 water figures were adjusted. Please refer to the Restatements section for the summary of changes

In 2023, as shown in Figure 9, 1,459,085.66 ML (57.14 percent) from the total water extraction came from surface water where 99.92 percent of this volume was utilized for our hydro power facilities. While on the other hand, the remaining 1,092,746.38 ML (42.80 percent) came from sea water which was utilized for our natural gas plants in FGCEC. The overall fresh ground water extraction of First Gen is only 1,542.86 ML which is only 0.06 percent of the 2023 overall extraction volume.

For our hydroelectric plant operations in Pantabangan and Masiway, the volume of water used in power generation is dependent on the volume of water required by the National Irrigation Authority (NIA) to be released from the reservoir for irrigation purposes. The volume of water extracted and discharged for our hydro plant operations in Table 2 is the surface water that passed through the First Gen facility turbines and was returned back to the receiving body of water.

While for our natural gas plants in FGCEC, 100 percent of the seawater extracted from Batangas Bay is used for once through cooling where it is eventually returned back to Batangas Bay.

Water consumption figures show a 11.18 percent decrease in 2023 compared to the previous year due to minimal well related activities (e.g., workover, quenching and drilling) for our geothermal plants in EDC and the combination of lower liquid fuel use of Santa Rita and Avion gas plants in FGCEC.

First Gen ensures that all wastewater generated by the assets are properly treated before discharged into the environment. Wastewater treatment facilities yield effluents compliant with quality standards before their release into receiving bodies of water. Moreover, effluent quality is regularly monitored for its compliance with DENR Department Administrative Order 2016-08 and the Philippine Clean Water Act of 2004.

These efficient water consumption practices and proper wastewater management systems contribute to First Gen’s consistent efforts to minimize the environmental impacts of its operations.

| FACILITY |

AREAS OF OPERATION

AND VALUE CHAIN

WHERE WATER IS USED

AND HOW IT IS USED |

WATER SOURCE |

POINT OF DISCHARGE AND

HOW EFFLUENTS ARE MANAGED |

|

Santa Rita

San Lorenzo

|

Groundwater (deep well) is used as feed water for the heat recovery steam generator (HRSG) boilers, and domestic purposes. Seawater is used in a one- pass process as cooling water to condense steam from HRSG. The condensate (water) is returned to the boilers for steam generation. |

Groundwater - two dedicated deep wells each for Santa Rita and San Lorenzo

Seawater - from Batangas Bay for once through cooling

|

Used water is treated in neutralization systems, oil-water separators, and sewage treatment plants before being discharged to Batangas Bay. The quality of effluents is monitored and analyzed in the in-house laboratory every other week by the O&M Contractor and quarterly by a third-party service provider recognized by the Department of Environment and Natural Resources-Environmental Management Bureau (DENR-EMB). No heavy metals are detected in Santa Rita, San Lorenzo, and San Gabriel effluents. A cooling water system is a once-through non-contact system, where seawater for cooling is returned to Batangas Bay upon passing through the condenser. Temperature change is monitored by getting the temperature difference between the daily temperature logs from the outfall and the intake. The physicochemical quality of seawater intake and discharge are being monitored every other week by the O&M Contractor and quarterly by a third-party service provider recognized by DENR-EMB. It is good to note that the cooling water discharges have no pollution load. No heavy metals are also detected from the cooling water discharge. |

| San Gabriel |

Groundwater - one dedicated deep well for San Gabriel |

| Avion |

Groundwater (deep well) is used in the cooling tower, for NOx control, and for domestic purposes. |

Groundwater - two dedicated deep wells for Avion Power Plant |

Used water is treated at the water treatment plant and discharged to the two retention basins for settling before final discharge. Oily wastewater is treated at the oil-water separators. The final effluents are discharged to the Cabubulag River and eventually to Batangas Bay. The quality of effluents is monitored and analyzed monthly by a third-party service provider recognized by DENR-EMB. |

| Agusan |

The plant is a run-of-river consisting of two 800-kW turbine generators that use water from the Agusan River to generate electricity. |

The Agusan mini-hydro plant is located in Damilag, Manolo Fortich, Bukidnon, 36 km southeast of Cagayan de Oro City in Northern Mindanao. Aside from power generation, the river also serves as a source for the irrigation system, especially in the upstream areas. |

The diverted water that runs the plant of two 800-kW turbine generators is being returned back to the river. |

| Pantabangan-Masiway |

Water is the main fuel for power generation. Water is sourced from the impounded water of the Pantabangan reservoir (NIA-owned).

Water released from PHEP from its tail water is the main source of fuel for power generation of MHEP, the facilities being cascading plants.

|

Water is sourced from the Pantabangan reservoir. The tributaries of the reservoir are 56 percent from Upper Pampanga and Carranglan River, 36 percent water discharge from Casecnan Hydroelectric Power, and 8 percent from Canili-Diayo dams.

Water is primarily sourced from the water discharged from the PHEP. Water is impounded via the Masiway reservoir and is capable of storing 6 million cubic meters of water.

|

Water discharged from the power plants through its tailrace goes directly to the Masiway reservoir. On the other hand, water discharge utilized for domestic use in the power plant passes through our Sewage Treatment Plant (STP) to ensure that our effluents are still within the prescribed environmental limits. Quarterly monitoring is being conducted upstream (Pantabangan reservoir) and downstream (Masiway reservoir) to ensure that the quality of our water being discharged is still within limits. |

| EDC Geothermal (BacMan, Leyte, Southern Negros, Mt. Apo) |

For its operation, EDC uses geothermal condensate for cooling but makeup freshwater is drawn as needed. Freshwater is also used for domestic purposes. |

EDC withdraws freshwater from river systems in the vicinity of the geothermal facilities, as well as from local water districts and water concessionaires. |

EDC follows the zero discharge system for its geothermal fluid collection and reinjection system (FCRS) to maximize recharge to the geothermal system. Minimal treated domestic wastewater is discharged, leading to the river system. |

| EDC Burgos |

Freshwater is used for domestic purposes |

Freshwater is withdrawn from local water districts and water concessionaires |

Domestic wastewater is subjected to sewage treatment facilities before being discharged |

| EDC Head Office |

| RBC Head Office |

| MANAGEMENT OF WATER-RELATED IMPACTS |

| FACILITY |

Minimum standards for quality of effluents discharged |

| Santa Rita |

The effluent quality of wastewater discharges follows the DENR. Administrative Order (DAO) 2016-08 and DAO 2021-19 Standards for Class SC Water. Initial parameters were identified in the Environmental Impact Statement, and additional priority parameters were added based on the prescribed parameters per industry classification in DAO 2016-08. |

| San Lorenzo |

| San Gabriel |

| Avion |

The effluent quality of wastewater discharges follows the DAO 2016-08 and DAO 2021-19 Standards for Class SC Water. |

| Agusan |

FG Bukidnon follows the Effluent standards prescribed parameters per industry classification in DAO 2016-08 and DAO 2021-19. FG Bukidnon also conducts and applies the DENR Approved Method of Analysis (Method of Standards) in its regular water testing at the plant to verify and ensure that the water passes the set water quality (e.g., pH, color, TSS, Oil and Grease, and BOD). FG Bukidnon has also secured a discharge permitunder Republic Act 9275 also or the Philippine Clean Water Act of 2004. |

| Pantabangan-Masiway |

FGHPC follows the general effluent standards indicated in the DAO 2016-08 and DAO 2021-19 |

| EDC Geothermal (BacMan, Leyte, Southern Negros, Mt. Apo) & EDC Burgos |

EDC follows the general effluent standards indicated in the DAO 2016-08 and DAO 2021-19. |

First Gen manages its wastes so that cross-contamination of non-hazardous and hazardous wastes are prevented from the point of generation, storage, transport, treatment, and disposal. The Company ensures that its wastes are managed according to the waste management hierarchy: elimination, reduction, reuse or recycling, treatment, and disposal according to RA 9003 (Philippine Ecological Solid Waste Management Act) and RA 6969 (Toxic Substances and Hazardous and Nuclear Wastes Control Act). The Company established an integrated waste management program to ensure that hazardous and non- hazardous wastes are stored, transported, treated, and disposed of according to regulatory requirements and standards. Due diligence of third-party service providers is carried out in compliance with regulatory requirements.

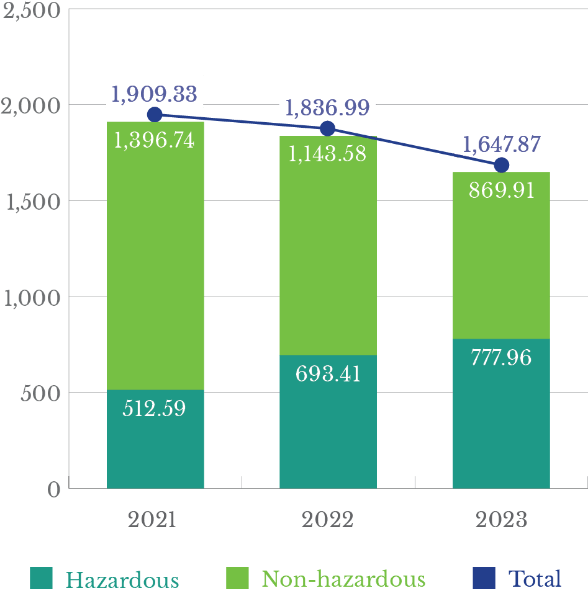

FIGURE 11: TOTAL WEIGHT OF WASTE GENERATED – HAZARDOUS AND NON-HAZARDOUS (TONNES)

The total weight of waste generated in 2023 was 10.30 percent lower compared to the previous year which was primarily contributed by the reduction of non-hazardous wastes. However, there was noted 12.19 percent increase in the weight of hazardous wastes generated due to the continued increase of activities in the operation and maintenance of our power plants.

For our natural gas plants at FGCEC Batangas, the generation of non- hazardous waste decreased since there was no major outage activity in 2023 compared with 2022. On the other hand, the noted increase in the generated hazardous waste for 2023 is attributed to the tank cleaning and painting activities done for the liquid fuel tanks in the tank farm.

For EDC, the increase in hazardous waste was due to the increase in activities at our sites such as drilling, drilling preparations, construction of growth projects (binary plants and battery storage) and general maintenance of our facilities.

FIGURE 11: TOTAL WEIGHT OF WASTE GENERATED – HAZARDOUS AND NON-HAZARDOUS (TONNES)

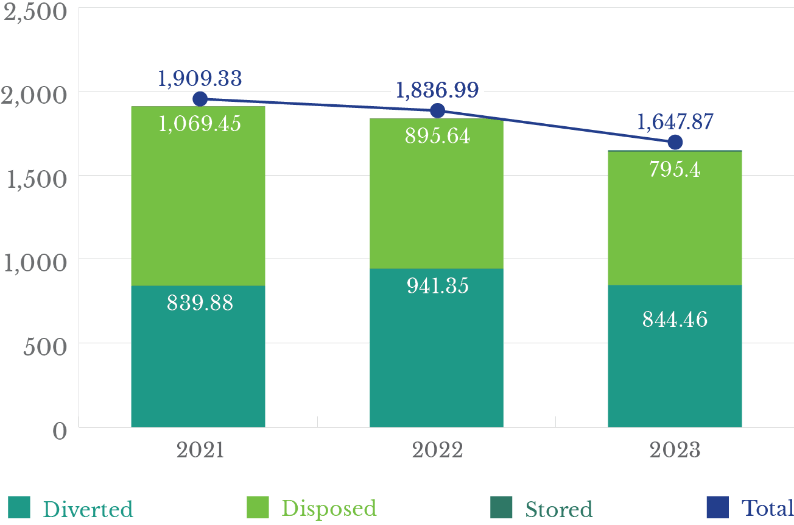

FIGURE 13: HAZARDOUS WASTE MANAGEMENT

(WEIGHT IN TONNES): DIVERSION VS DISPOSAL

(IN PERCENTAGES)

FIGURE 13: HAZARDOUS

WASTE MANAGEMENT (WEIGHT IN TONNES):

DIVERSION VS DISPOSAL (IN PERCENTAGES)

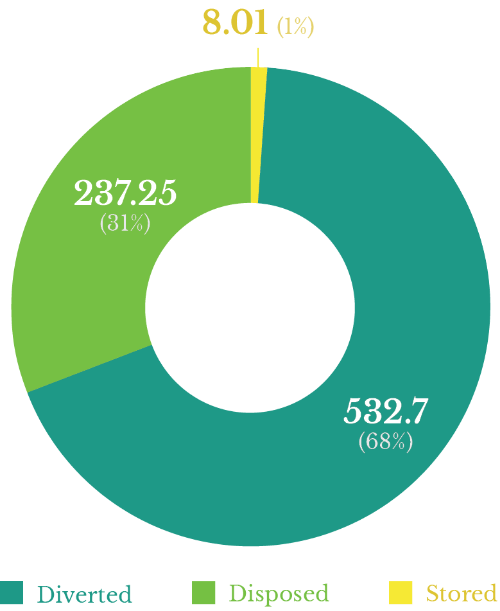

For 2023, 68 percent of the hazardous waste generated was diverted (composed of recyclable or recoverable materials) which was primarily contributed by the recycling of used oil, used batteries, and electronic wastes.

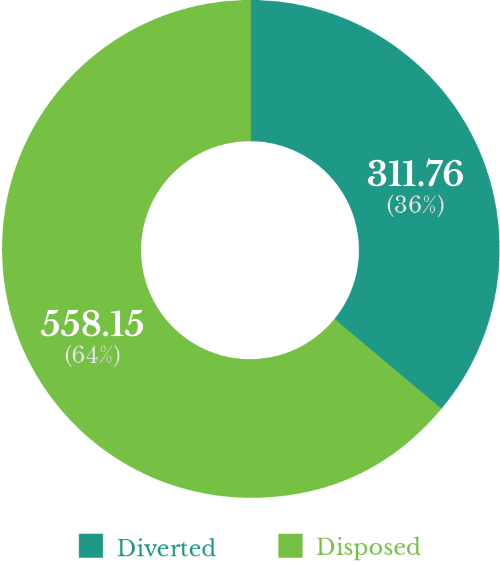

For 2023, 36 percent of the non-hazardous waste generated was diverted through composting and recycling of materials

FIGURE 13: HAZARDOUS WASTE MANAGEMENT

(WEIGHT IN TONNES): DIVERSION VS DISPOSAL

(IN PERCENTAGES)

For 2023, 68 percent of the hazardous waste generated was diverted (composed of recyclable or recoverable materials) which was primarily contributed by the recycling of used oil, used batteries, and electronic wastes.

FIGURE 13: HAZARDOUS

WASTE MANAGEMENT (WEIGHT IN TONNES):

DIVERSION VS DISPOSAL (IN PERCENTAGES)

For 2023, 36 percent of the non-hazardous waste generated was diverted through composting and recycling of materials

| MANAGEMENT OF SIGNIFICANT WASTE-RELATED IMPACTS |

| Activity/Process |

Waste Management |

Impact Management |

Outcome |

| Hazardous and Nonhazardous Wastes generated from Company operations |

Storage:

Hazardous wastes are labeled, segregated, and stored in hazardous wastes storage building

Transport and Disposal:

Hazardous wastes are transported by the DENR accredited transporter and delivered to DENR accredited treatment storage and disposal (TSD) facility for proper treatment. Non-hazardous wastes are disposed of through the Local Government Unit

Waste Minimization:

To minimize waste generation, use of materials are optimized through proper maintenance, spill prevention measures, use of appropriate-sized materials, paper recycling, and paperless transactions

|

- Established guidelines on proper handling, storage, and disposal of wastes

- Prevention of spills that may potentially contaminate storm drains and water bodies

- Utilized the Company’s in-house neutralization system

- Complied to fire safety requirements

- Monitored weekly the hazardous waste storage building

- Conducted due diligence audit of transporter and TSD facilities

- Partnered with ABS-CBN Lingkod Kapamilya Foundation - Bantay Kalikasan for recycling of waste oil, lead and plastic casing of batteries

|

- Complied with legal and regulatory requirements

- No spill incidents resulting in release to environment

|

First Gen maintains environmental programs and information education campaigns (IEC) that primarily raise climate change awareness and encourage climate action among its employees, customers, communities and partner stakeholders.

In 2023, the First Gen CSR team led the implementation of the following programs:

Climate in 2 Minutes is now on its third year, third season which promotes to uncover the stories, the science, and solutions to help protect our planet for future generations.

The season of Climate in 2 Minutes sheds light on the challenges we face and provides insights on how we can work together to build a better future for everyone. Employees can join the mission to understand the impacts of climate change on our planet and the people living in it.

In partnership with Junk Not, the First Gen EmPOWER Employee Volunteers organized a Plastic Collection Drive, in support of the Company’s Mission for regeneration. The program involves the collection, sorting and donation of certain plastic wastes that can be recycled and reprocessed into useful home and work pieces.

Our CSR Group collaborated with the FPH Human Resources Group for the Lobo Interactive Adventure: An Earth Day Special last April 26, 2023. The virtual event aimed to debut and introduce the online adventure platform jointly developed by First Gen and MAD Travel, while inculcating the systems-thinking approach in dealing with community issues.

The platform features Lobo, Batangas, as part of the Verde Island Passage (VIP), known as the “center of center of marine biodiversity”. During the event, sixty attendees from the various Lopez Group companies and foundations had the opportunity to explore the different location ins Lobo and learn more about the area’s protection and conservation activities. The attendees were able to actively participate in navigating the platform by casting their choices through the Zoom poll, which included obtaining the three keys to sustainability in the latter part of the platform through a quiz.

First Gen highly values our commitment to the protection and improvement of the environment and the ecosystems where we operate our business because the resources provided by nature are essential to achieve growth and ongoing value creation by providing clean and renewable energy to bolster our country’s energy security.

Mini-Mangrove Forest

FGCEC maintains a 10-hectare mangrove area within the complex that has the potential to sequester carbon at a rate of approximately 88.4 tons/Ha. Located within the host barangays of Sta. Clara and Sta. Rita Aplaya of Batangas City, this mangrove forest also functions as a seat of biodiversity by providing a suitable habitat to an array of both aquatic and terrestrial species. The mangrove forest stabilizes the shorelines, reduces erosion, and protects its vicinity from flooding and storm surges.

Based on the monitoring study conducted in May 2023, there was an observed increase of 3.3 percent in the diameter to breast height (DBH) ratio which is a growth indicator for the mangroves that are being maintained. In 2023, a total of 2,098 mangroves seedlings of various species are being nurtured in the FGCEC nursery, that can be used for future mangrove planting activities.

Use of Seashells as Raw Materials for Paving Blocks

FCGEC continues to implement its program that focuses on the use of seashells as raw materials in the production of pavers. Launched in 2021, the project aims to provide an alternative use for the seashells collected when cleaning the FGCEC pipeline system as opposed to sending them for disposal to landfills. In 2023, approximately 30,000 kg of seashells were used as aggregates in the production of 50,000 pieces of pavers, which will be donated to the Batangas City Ecopark for the construction of pathways in the area. This has resulted in three percent reduction in the total amount of non-hazardous residual wastes that was being dumped in sanitary landfills through its diversion as a useful aggregate in the production of a new product.

Adopt-a-River/Water Body Program

First Gen also continues its long-term partnership with the DENR under the Adopt-a-River/ Water Body Program, which aims to protect and enhance the Cabubulag River in Brgy. Sta. Clara, Batangas City through regular water quality monitoring and cleanup activities. The Cabubulag River Clean-up was conducted from October 16 to November 23, 2023 for the entire stretch of the river that flows within the complex. The cleanup activities resulted in the removal of a total of 1,843 kilograms of wastes from the river and its banks.

In our continuing effort to be one of the country’s leaders in environmental conservation, the BINHI Program is the nationwide greening program of EDC, our renewable energy subsidiary. BINHI collaborates with the country’s top foresters, botanists, and wildlife biologists with the aim to reforest degraded watersheds; rescue, secure, and mainstream native Philippine tree species; safeguard forests and watershed; and conserve the diverse flora and fauna that thrives within EDC’s geothermal reservations. In 2023, EDC has demonstrated its commitment to this cause by investing PhP 27 million in the various environmental initiatives and projects organized under the BINHI program.

Forest Protection

EDC, through the BINHI program, engages in the comprehensive management of the forests and watersheds surrounding its project sites and has committed to the role of a watershed manager in Bacon-Manito (Bacman), Negros Oriental, Leyte and Mt. Apo. EDC’s forest protection initiatives range across 127,608 hectares of forest lands within the four geothermal reservations where it is active.

In 2023, EDC, in collaboration with its local partners, successfully concluded 2,698 kilometers of foot and drone patrols within designated conservation areas of focus. Forest patrols last year resulted in the confiscation of a total of 1,680 board feet of confiscated lumber, 63 poles of rattan, and the stopping of one case of conveyance. Involved individuals and confiscated items were turned over to the DENR.

The deliberate forest patrols and heightened patrol visibility implemented within the geothermal reservations also played a crucial role in averting forest fires, leading to zero reported incidents in 2023.

Forest Restoration

The BINHI program enables EDC to actively contribute to the restoration of open and denuded forests and watersheds. Since the conception of the BINHI program in 2008, EDC has partnered up with 88 forest communities to plant over 10,000 hectares nationwide, cementing its position as the largest private sector-led reforestation effort. In collaboration with DENR and local communities, EDC goes beyond conventional tree planting by placing emphasis on the cultivation of indigenous forest tree species.

EDC’s vegetative material reproduction nurseries serve to cultivate seedlings of native Philippine trees for utilization as planting materials for diverse forest restoration projects. In 2023, EDC successfully cultivated 451,140 high-quality seedlings in both central and satellite nurseries strategically positioned across its project sites. These seedlings were in turn distributed to various partners for use in tree-planting activities while a seedling stock is currently under careful maintenance in nurseries for future initiatives.

In May 2023, also through the BINHI program, establishment, maintenance, replanting, and enhancement planting activities in the 1,209 hectare plantation at the Pantabangan-Carranglan Watershed Forest Reserve (PCWFR) were conducted. The PCWFR is located within the vicinity of First Gen’s hydroelectric power plant in Pantabangan, Nueva Ecija.

In terms of moving forward plans, EDC, the Asian Forest Cooperation Organization (AFoCO), and the DENR - Forest Management Bureau (FMB) signed a Memorandum of Understanding in 2023 for the project titled: Forest Restoration Using Philippine Threatened and Endemic Tree Species (PTES) in Bacon-Manito Geothermal Reservation in support to the Philippines’ Forestry Sector’s National Greening Program. The objective of the project is to increase area of forest cover in Bacman in the provinces of Sorsogon and Albay. In addition, the project will restore 100 hectares of disturbed forest with 20 different species of highly threatened and endemic trees in support of the Philippine forestry sector’s National Greening Program.

First Gen acknowledges that the preservation of biodiversity is paramount for the long-term sustainability of ecosystems surrounding its operating assets. As the operating business units and the project sites also serve as the habitats for wildlife species, the continued dedication to biodiversity preservation demonstrates First Gen’s core belief that it is possible to build and maintain balanced and sustainable relationship between business activities and the natural environment.

First Gen monitors and documents a wide variety of wildlife species using the International Union for Conservation of Nature (IUCN) Red List which include fish, reptiles, amphibians, and mammals. The monitoring of said wildlife is primarily done within the EDC sites and FGCEC. In 2023, First Gen documented a total of 549 species for EDC sites and 112 species for FGCEC.

First Gen’s biodiversity conservation efforts are primarily focused on EDC’s Biodiversity Conservation and Monitoring Program (BCMP) since several EDC sites are operating in key biodiversity areas and/or natural parks. The BCMP is implemented by an in-house team comprising wildlife biologists and foresters and in collaboration with key institutions such as the University of the Philippines Institute of Biology (UP-IB), Silliman University in Negros Oriental, and the Philippines Biodiversity Conservation Foundation, Inc. (PBCFI) in Negros Occidental.

In 2023, on top of the in-house conduct of regular biodiversity monitoring activities, EDC executed activities under the third phase (BCMP III) of its sustained environment program on BCMP together with UP-IB and HerpWatch Pilipinas. The biodiversity metrics component of BCMP III aims to develop an assessment and monitoring tool using faunal and floral communities as bioindicators in both freshwater and terrestrial forest ecosystems with the intended goal of being adopted as the standard for ecosystem health assessment and monitoring throughout the country.

First Gen also understands that communicating the data obtained from its conservation activities is crucial as it helps bridge the gap between scientific knowledge and the broader public, policymakers, and other stakeholders. In 2023, EDC co-hosted the 31st Annual Symposium of the Biodiversity Conservation Society of the Philippines. With over 250 participants from different academic and research institutions, government agencies, non- government organizations (NGOs), independent researchers, undergraduate and graduate students from different schools in the Philippines, the Biodiversity Conservation of the Philippines (BCSP) conducted their 31st annual Philippine Biodiversity Symposium with the theme “Priority Conservation Actions to Sustain Philippine Biodiversity” at Sorsogon State University (SSU) from August 22-25, 2023 with the goal of advancing and improving biodiversity research and conservation as well as increasing public awareness, appreciation, and understanding of Philippine biodiversity.

STRATEGY

PURSUED |

WHERE WE

PROGRESSED

IN 2023 |

IMPACT

MATERIALITY |

FINANCIAL

MATERIALITY |

OUR PLANS |

|

Grow our portfolio to 13GW Efficiently

Efficiently operate on low-carbon portfolio

|

GHG Emissions

Increased absolute value of Scope 1 Emissions

Increased emission intensity

|

Planet

Decrease in natural capital due to the use of natural gas (fossil fuel) as a transition fuel

|

Investors

Increase in manufactured and financial capital due to the increase in generation

|

Continue feasibility studies in the pre-development of future renewable energy projects

Continue monitoring updates on emerging technologies that can further decarbonize our gas plants

|

|

Enable the organization

|

GHG Emissions

Implementation of capacity building on:

- Scope 3 emissions accounting

- IFRS S1 and S2

Identified and calculated the material Scope 3 emission categories

|

Employees/

Subsidiaries

Increase in the knowledge and understanding of First Gen key personnel who are involved in the development and implementation of ESG programs and initiatives

Increase in knowledge and understanding in the accounting and calculation of Scope 3 emissions

|

Investors

Increase in manufactured capital due to improved compliance to TCFD and IFRS S2 on Scope 3 emissions reporting

|

Improve existing processes to account and consolidate material Scope 3 Categories

Continue monitoring the development of compliance requirements for climate strategy on management of GHG emissions.

Continue implementing employee capacity building programs for ESG best practices and compliance requirements

|

|

Create Total Stakeholder value

|

GHG Emissions

Completed the GHG assurance project - Readiness Assessment for external limited assurance of GHG data |

Investors

Initiated steps to prepare and comply with TCFD and IFRS S2 requirements on external assurance of GHG data

|

Investors

Increase in manufactured capital due to preparatory activities for improved compliance to TCFD and IFRS S2 on external assurance of GHG emissions

|

Prepare for an external limited assurance of our GHG accounting and monitoring processes

|

|

Create Total Stakeholder value

|

Energy Efficiency

Use of solar panels for house load energy consumption

Continue pilot testing and purchasing of additional electric vehicles

|

Planet

Increase in natural capital due to the utilization of RE sources for house load and electronic vehicles

Investors

Increase in manufactured capital due to higher generation with optimized fuel and energy consumption

|

Investors

Increase in financial capital due to reduction of costs of purchased electricity for house load

Decrease in financial capital due to the associated investment costs for solar panel installation and purchase of electric vehicles

|

Continue identification of opportunities to improve house load and efficiency of plant equipment to generate more energy at lower fuel consumption

Develop strategies at the plant level to address improvement opportunities identified from the energy audit

|

|

Create Total Stakeholder value

|

Water Utilization

Decrease in water consumption

Wastewater Management

Continuous compliance of water discharge quality to DENR effluent standards

|

Planet and Host Communities

Increase in natural capital – availability of water

Preservation of the quality of water bodies due to compliance of water discharge

Government

Sustainment of compliance with legal and regulatory requirements

|

Investors

Increase in manufactured and financial capital due to the increase in generation for the use of water resource

Preservation of financial capital – no fines and no remediation costs due to zero environmental-related incidents

|

Identify and establish the appropriate water management utilization targets

Sustain compliance of our water discharge properties to DENR effluent standards

|

|

Create Total Stakeholder value

|

Waste Management

Decrease in total volume of waste generated

Increase in total volume of waste diverted

Wastes generated are disposed in compliance to DENR standards and requirements

|

Planet

Reduction of wastes disposed through land fill

No spill incidents resulting in release to environment

Government

Sustainment of compliance with legal and regulatory requirements

|

Investors

Preservation of financial capital – no fines and no remediation costs due to zero environmental-related incidents

Reduction in the financial capital due to the associated costs needed for the transportation and disposal of hazardous wastes

|

Identify and establish the appropriate waste management and reduction targets

Sustain compliance of our waste management processes to applicable DENR standards

|

|

Create Total Stakeholder value

|

Conservation of the Natural World

Sustainment of FGCEC’s Programs

- Mini Mangrove Forest

- Adopt-a-River Program

Sustainment of EDC Programs

- BINHI

- Biodiversity Conservation and Monitoring Program

|

Planet and Host Communities

Preservation of the natural capital resources

Preservation of our social license to operate within our areas of operation

Investors

Increase in the social and relationship capital due to the sustainment of initiatives that are aligned with First Gen’s mission

Government

Stronger relationship and partnership with the government due to the collaboration efforts in the protection of forest and water habitats

|

Investors

Reduction in financial capital due to the associated costs to implement the various biodiversity programs for the protection of flora and fauna in both forest and water habitats

Preservation of the manufactured capital due to attainment of social license to operate from the host communities and collaboration with the government in the protection of natural resources

|

Sustainment of biodiversity programs of First Gen

|